The Miracle Of 4000w CNC Laser Cutting Machine: A Revolution In Precision Manufacturing

products description

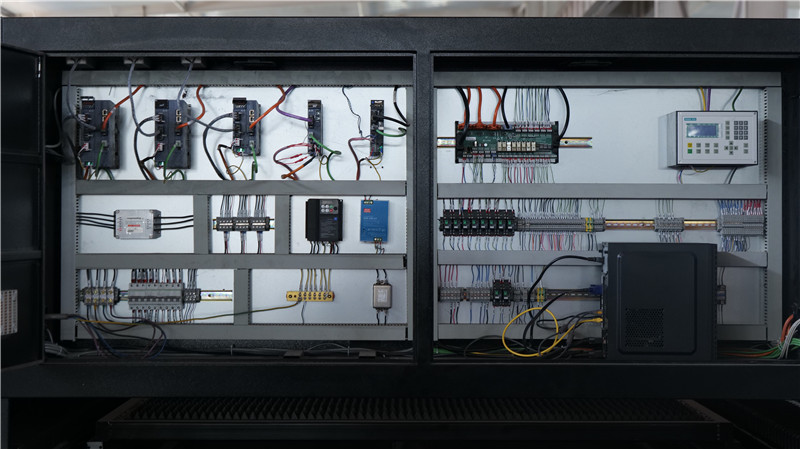

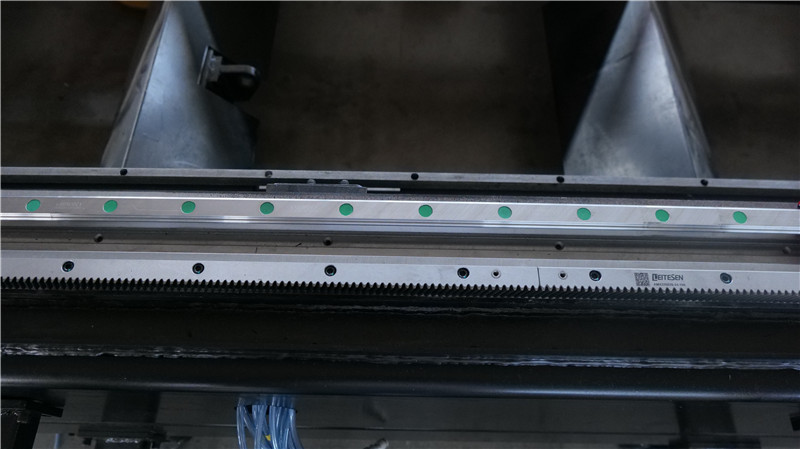

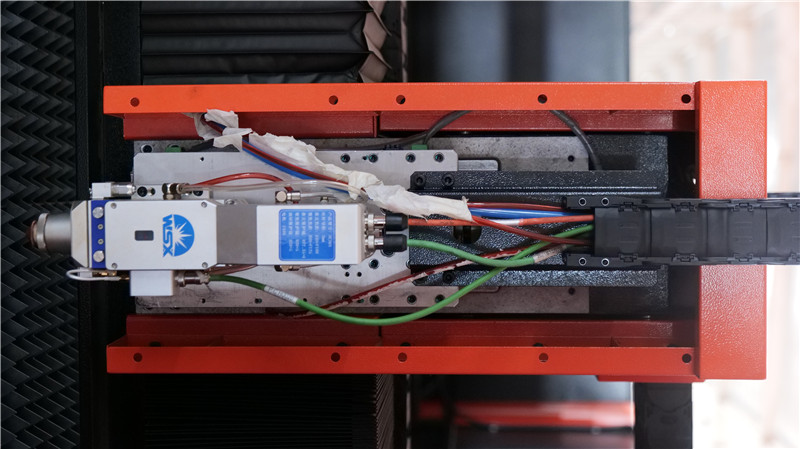

DRIVEN SYSTEM

■The X,Y, Z axes all adopt imported servo motors, equipped with high-performance precision reducers and high-efficiency transmission mechanisms such as grinding racks and pinions, high-precision linear guides, etc.,which effectively ensure the transmission accuracy;

■Beam transmission adopts gantry type bilateral drive syn-chronous compensation technology, which has high rigidity, high precision, strong and reliable, and good stability.

BEAM

lt adopts steel plate bending and welding method, rough machining after annealing to eliminate internal stress, and finishing after secondary vibration aging treatment, which ensures the overall strength, rigidity and sta- bility of the beam.

BED FRAME

■The machine bed adopts an integral weld-ing structure, which is rough machined after annealing to eliminate internal stress, and finished after natural aging completely elimi-nates internal stress, thus greatly improving the stability of the machine tool.

We offer a variety of CNC hot sale fiber laser metal cutting machines to meet your needs, including the latest models from top manufacturers. Our selection includes both desktop and industrial-grade options with varying power levels, and we can help you choose the best machine for your specific application and budget. Please contact us directly if you would like more information or assistance selecting a machine that is right for you.

detail show

Introduce:

In the rapidly evolving world of manufacturing, precision and efficiency are key drivers of success. The 4000w CNC laser cutting machine is a breakthrough invention that revolutionizes the production process. This state-of-the-art technology revolutionizes manufacturing by delivering unparalleled precision, speed and versatility. In this blog post, we will explore the amazing capabilities of the 4000w CNC laser cutting machine and how it is reshaping various industries.

1. Unparalleled accuracy:

The 4000-watt CNC laser cutting machine has superior precision that exceeds traditional cutting methods. With a laser focus as small as 0.1 mm, the machine is able to precisely cut a wide range of materials with impeccable precision. Whether it's metal, plastic, wood, or even delicate fabrics, the laser's sharp beam enables clean, intricate cuts, making it ideal for industries such as aerospace, automotive, and electronics that demand perfect precision.

2. Lightning-fast operation:

Time plays a vital role in any manufacturing process, and the 4000w CNC laser cutting machine effectively shortens production time. With its high-power laser, the machine can seamlessly cut materials at incredible speeds, significantly shortening production cycles. Additionally, it eliminates the need for manual operations and repositioning, allowing businesses to meet tight deadlines and achieve higher productivity.

3. Optimum Versatility:

4000w CNC laser cutting machines push the limits in materials and design complexity. It can cut a variety of materials with ease, including stainless steel, aluminum, acrylic, leather, and more. In addition, the machine can create complex shapes, intricate patterns and personalized designs, unlocking endless possibilities for designers and manufacturers.

4. Improve cost-effectiveness:

Using a 4000w CNC laser cutting machine can significantly reduce the operating costs associated with traditional cutting methods. Because the technology streamlines the production process, it minimizes material waste, simplifies labor requirements, and reduces the need for secondary finishing. Additionally, its long lifespan and minimal maintenance ensure long-term cost savings for businesses, making it a worthwhile investment in any industry.

5. Environmentally friendly manufacturing:

Sustainability is a growing concern around the world, and manufacturers are actively seeking greener alternatives. The 4000w CNC laser cutting machine fits perfectly with this vision. It wastes minimal material, 10 times less than traditional methods, significantly reducing environmental impact. Additionally, being energy-efficient machines, they consume less electricity during operation, further contributing to a greener manufacturing process.

In conclusion:

The advent of the 4000W CNC laser cutting machine has opened a new era of precision manufacturing and promoted various industries towards unparalleled efficiency. Its exceptional accuracy, lightning-fast operating speed, versatility, cost-effectiveness and environmentally friendly attributes make it an indispensable tool for manufacturers worldwide. As technology continues to advance, it’s safe to say that 4000w CNC laser cutting machines will continue to push the boundaries of contemporary manufacturing.