The Evolution Of CNC Sheet Metal Press Brakes: From Manual To Automatic

Video

products description

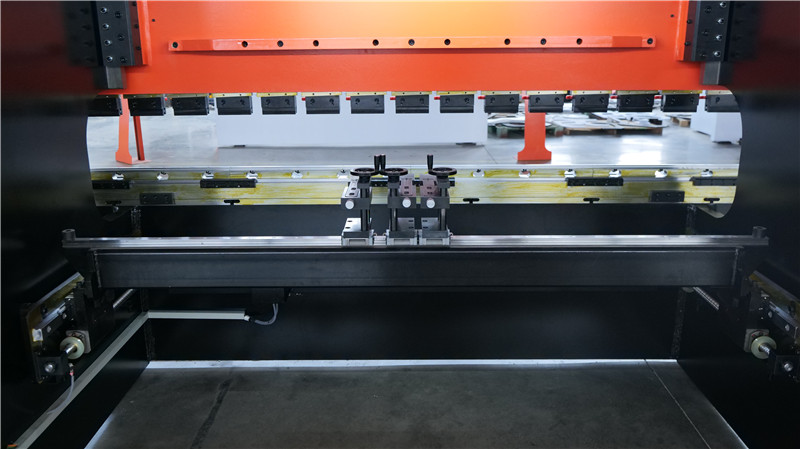

Bending methods include angle bending, absolute value bending and great arc bending.

IInclude upper and lower tool libraries, each library has 50 tools forediting. Program preview and program

Selection functions.

II/O diagnosis function, timely diagnose the problems of the system and equipment.

Workpiece counting function, the counter increases by one every time the program runs

X-axis front limit function, by setting the X-axis front limit in the lower mold parameters.

Pull& move delay function.

The deflection compensation adopts the mechanical compensation method to improve the stability of the product.

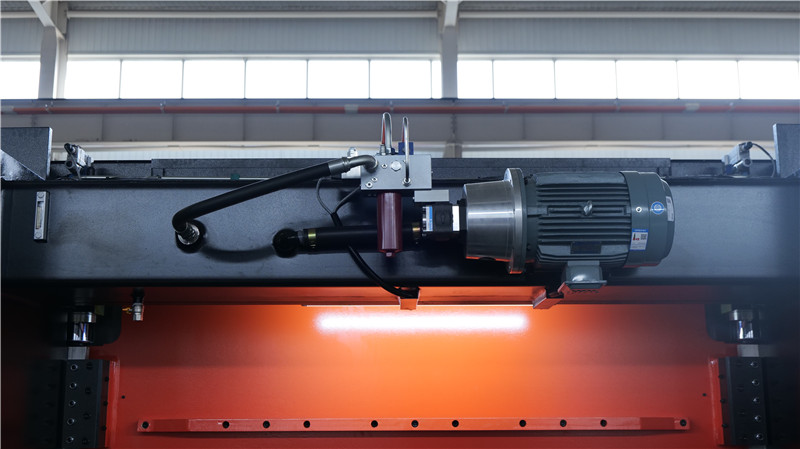

IAutomatic stop function of hydraulic motor, automatic stop in idle time to achieve energy saving effect.

Hydraulic oil replacement reminder function,automatic reminder to replace hydraulic oil after 900 hours of running.

products specification

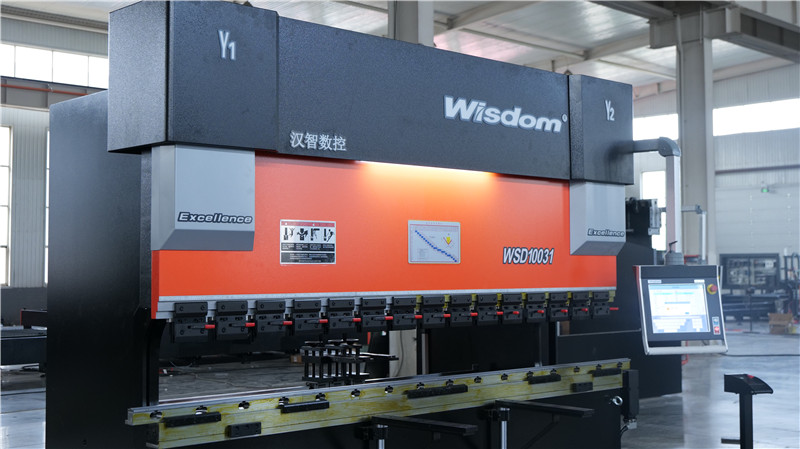

| Product branda CNC bending machine | Tablelength(mm) 3100mm | |

| Model WSD10031 | Column spacing(mm) 2600mm | |

| Processing capacity 100T | Table heighi 790mm | |

| Numerical contolsystem DELEMLaimore | Throat depth(mm) 400mm | |

| Servo system Fuji | Stroke ofram mm 200mm | |

| Servo motor Fuji | Closed height(mm) | |

| Pressure relief valve group Yuken | Approaching speed(mm/sec) 160 | |

| Magnetic scale GIVI | Working speed(mm/sec) 10 | |

| Hydraulic seal ring NOK(Japan) | Return speed(mm/sec) 130 | |

| Limit switch OMRON[Japan] | Main motor(KW) 7.5KW | |

| Force(KN)1000KN | Weight(KG)8700 | |

| WSD CNC Pressbrake Series specifications Dimension (mm)L*W*H | |||||||||||||

| WSDMode | WSD50/12 | WSD63/25 | WSD100/31 | WSD100/40 | WSD160/32 | WSD160/40 | WSD220/32 | WSD220/40 | WSD250/40 | ||||

| Standaro | Curtain Wallndustry | ||||||||||||

| Force KN | 500 | 630 | 630 | 1000 | 1000 | 1000 | 1000 | 1600 | 1600 | 2200 | 2200 | 2500 | |

| Bending length mm | 1220 | 2500 | 2500 | 3100 | 4000 | 4000 | 4000 | 3200 | 4000 | 3200 | 4000 | 4000 | |

| Column distance mm | 1160 | 2100 | 2100 | 2600 | 3300 | 3300 | 3300 | 2700 | 3300 | 2700 | 3300 | 3300 | |

| Norktable heightmm | 770 | 760 | 760 | 790 | 790 | 790 | 790 | 790 | 790 | 790 | 790 | 810 | |

| Stroke of ram mm | 200 | 150 | 200 | 200 | 200 | 200 | 250 | 200 | 200 | 200 | 200 | 250 | |

| Closed height mm | 410 | 420 | 470 | 470 | 470 | 470 | 520 | 470 | 470 | 470 | 470 | 520 | |

| Throat depthmm | 255 | 250 | 250 | 400 | 400 | 500 | 500 | 400 | 400 | 400 | 400 | 400 | |

| Throat heightmm | 540 | 500 | 500 | 550 | 550 | 550 | 575 | 530 | 530 | 530 | 530 | 570 | |

| Speed of rammm/s | cpproacing | 180 | 130 | 130 | 160 | 160 | 160 | 160 | 130 | 130 | 120 | 120 | 110 |

| working | 15 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 9 | 9 | 9 | |

| retur | 180 | 110 | 110 | 130 | 130 | 130 | 130 | 100 | 100 | 95 | 95 | 95 | |

| -axis strokemm | 500 | 500 | 500 | 500 | 500 | 600 | 500 | 500 | 500 | 500 | 500 | 500 | |

| Bacxgouge posiion irid gode]mm | 900 | 900 | 900 | 900 | 900 | 1000 | 850 | 900 | 900 | 900 | 900 | 900 | |

| Main motor Kw | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 | 11 | 11 | 15 | 15 | 18.5 | |

| 4000 | 4700 | 5700 | 8700 | 9300 | 9500 | 9500 | 11400 | 13400 | 14100 | 15200 | 20000 | ||

| Dimensionmm | L | 1600 | 2690 | 2690 | 3250 | 4080 | 4200 | 4150 | 3360 | 4080 | 3370 | 4080 | 4250 |

| W | 1580 | 1370 | 1370 | 1610 | 2600 | 2000 | 1710 | 1810 | 1810 | 1850 | 1850 | 1850 | |

| H | 2470 | 2570 | 2570 | 2610 | 1570 | 2720 | 2810 | 2720 | 2720 | 2810 | 2810 | 2910 | |

Manual sheet metal bending machines have been used for decades and require the operator to physically manipulate the metal to achieve the desired bend. While these machines served their purpose, they were limited in accuracy and productivity. Additionally, the physical labor required to operate these machines often results in worker fatigue and increases the risk of injury.

The introduction of automatic bending machines marks a major shift in the industry. Automatic sheet metal bending machines, automatic sheet metal bending machines and other automatic bending machines have completely changed the sheet metal bending process. These machines are equipped with advanced features including computer controls, precision machining tools and programmable settings to achieve high levels of accuracy and repeatability.

One of the most significant advancements in automatic bending machines is the incorporation of CNC (computer numerical control) technology. CNC sheet metal press brakes offer unparalleled precision and flexibility to complete complex bending operations with minimal setup time. The ability to program specific bending sequences and angles makes CNC press brakes indispensable in modern metal fabrication facilities.

In addition to CNC technology, modern automatic bending machines also feature advanced hydraulic and mechanical systems. For example, a 110 ton press brake is capable of exerting tremendous force to bend heavy sheet metal. The combination of high tonnage and automated controls makes these machines ideal for a variety of applications, including the production of structural components, housings and automotive parts.

The transition from manual to automatic press brakes has had a profound impact on the manufacturing industry. Companies using these advanced machines report significant improvements in productivity, cost savings, and overall product quality. The ability to produce complex and precise bends with minimal human intervention simplifies the production process and reduces the margin for error.

In addition, automatic press brakes improve workplace safety by minimizing operator physical stress and reducing the risk of accidents. With automated controls and safety features, these machines provide reliability and consistency previously unachievable with manual bending methods.

In short, the evolution of sheet metal bending machines from manual to automatic has changed the manufacturing landscape. 6-axis press brakes, CNC sheet metal press brakes, 110 ton press brakes and automatic press brakes have revolutionized the way metal is fabricated, delivering unparalleled precision, efficiency and safety. As technology continues to advance, we are likely to see further innovation in the field of automatic bending machines, further enhancing manufacturing capabilities.

detail show