The Best Handheld Metal Laser Welding Machine

Laser welding machines have revolutionized the way metal parts are connected in various industries. Their ability to seamlessly join metals together using concentrated laser beams makes them indispensable in industries such as automotive, aerospace and medical. Among the different types of laser welding machines available in the market, handheld metal laser welding machines are considered to be one of the best options for versatility, efficiency, and ease of use.

A handheld metal laser welder is a compact, portable device that enables operators to weld metal parts with precision. It provides the flexibility to operate in a variety of positions and angles, ensuring welders can reach tight spaces and complex joints. This exceptional flexibility makes it ideal for industries requiring complex welding processes.

One of the standout features of handheld metal laser welders is their ease of setup and operation. It eliminates the need for large equipment, reducing setup time and effort required. Welders can now perform welding tasks efficiently and easily. This convenience is advantageous for industries that require quick turnaround times and high-volume production.

The precision and accuracy of handheld metal laser welders is unmatched. The focused laser beam ensures that the target area receives heat evenly, preventing any deformation or damage to surrounding materials. The result is a clean, strong and durable welded joint. This level of accuracy is particularly important in industries such as aerospace and medical, where the quality and reliability of welded joints are critical.

In addition to superior welding capabilities, handheld metal laser welders offer a range of other benefits. Its non-contact welding process reduces the risk of contamination and damage to the work surface. It also eliminates the need for additional materials such as filler metal, flux or shielding gas, further reducing costs and increasing productivity.

When considering purchasing a welding machine, it is essential to choose one that meets your specific requirements. The best handheld metal laser welding machine for sale should have the appropriate power output, pulse duration, and laser wavelength for your intended application. It should also be equipped with user-friendly features that make it easier for the operator to navigate and control the machine.

Additionally, when purchasing a handheld metal laser welding machine, it is crucial to choose a reputable and reliable manufacturer or supplier. Look for a company with a proven track record of delivering high-quality products and excellent customer service. They should provide comprehensive technical support, training, and warranty to ensure the machine performs optimally and meets your expectations.

All in all, a handheld metal laser welder is a versatile and efficient tool for joining metal pieces together. Its compact size, ease of use and exceptional accuracy make it an excellent choice for a variety of industries. When looking for the best welding machine for sale, it is essential to consider your specific requirements and choose a reputable manufacturer or supplier. With the right handheld metal laser welding machine, you can achieve superior weld joints and increase the productivity of your welding process.

Video

Application

Laser welding is a type of welding that uses a laser to melt the material being joined. It has applications in many industries, such as automotive, aerospace, and medical device manufacturing. Laser welding can be used for joining difficult-to-weld materials, including aluminum and stainless steel alloys. It also creates more precise welds than traditional welding techniques due to its precision and accuracy.

laser welding machine Precautions for use

1. Wear protective clothing, gloves and glasses when operating the laser welding machine. 2. Please confirm that all parts of the machine are well maintained and in good condition before use. 3. Ensure that the work area is well ventilated to prevent the accumulation of hazardous substances due to welding operations. 4. During the operation of the laser welding machine, please pay attention to potential dangers such as fire, smoke or sparks. 5. Check for loose connections or defective wiring before use, and take necessary precautions if necessary to avoid any electrical shock hazard associated with the machine's power supply or its internal components/circuits. 6. When performing laser welding operations on metals such as steel and aluminum, a safe distance should be kept from flammable substances such as paper and plastic, which are flammable under certain conditions. 7. Do not overheat the material by running pulses that are too long, this can deform the welded part or cause thermal damage to the surrounding area. 8. Take care to discard the hot pieces that come off after the soldering process.

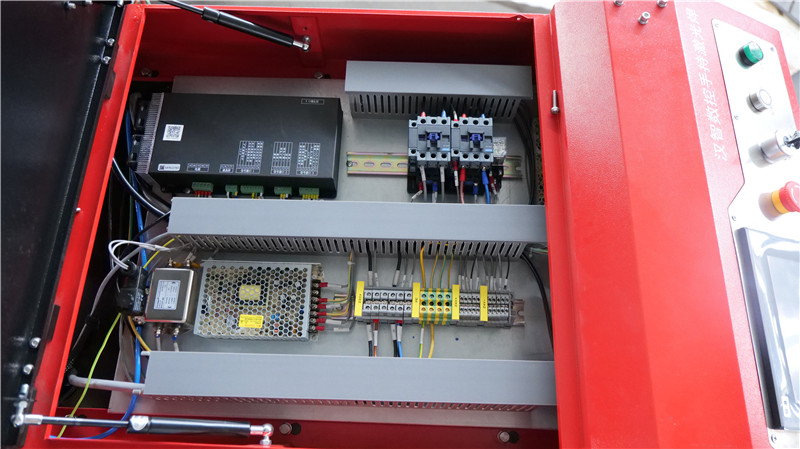

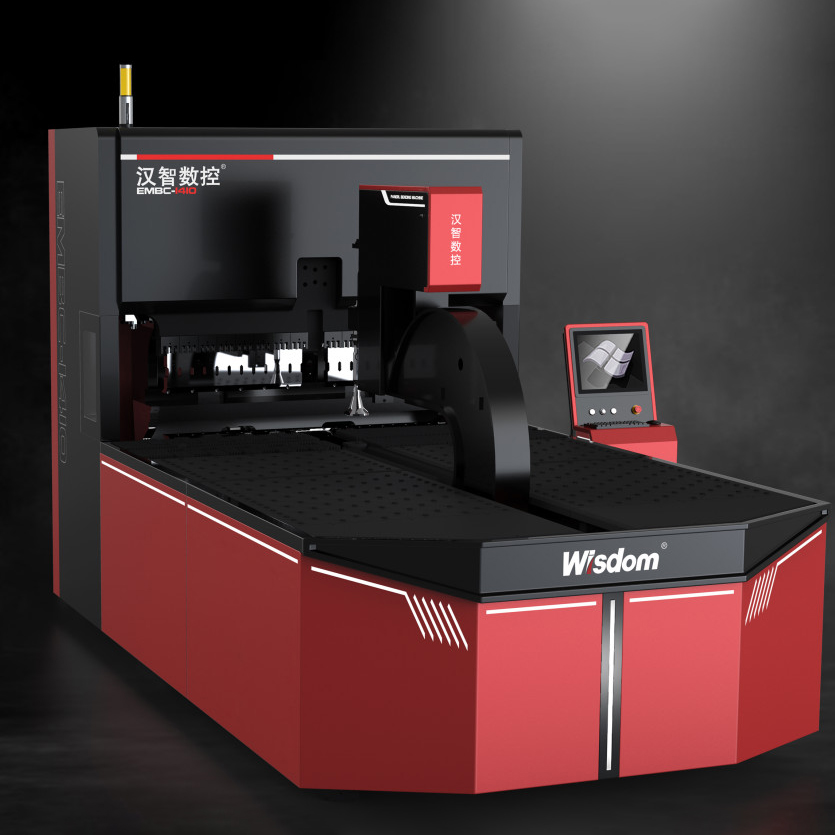

detail show