Improving Precision And Efficiency: The Indispensable Role Of CNC Hydraulic Bending Machines In Modern Metal Bending

Video

products description

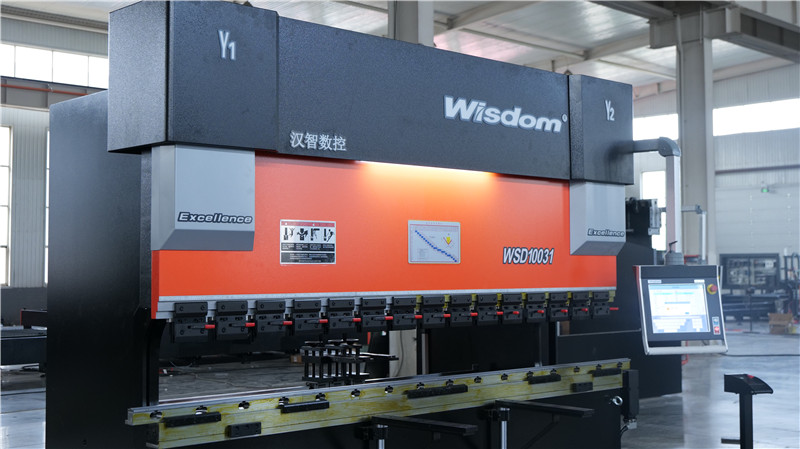

Launched CNC hydraulic bending machine:

CNC hydraulic bending machines are machines specifically designed to bend metal sheets into various shapes and forms. This powerful piece of equipment uses hydraulic force to apply pressure to sheet metal, allowing it to bend sheet metal accurately and consistently to meet a variety of manufacturing needs. Its computer numerical control (CNC) system precisely controls the bending process, ensuring exceptional accuracy and repeatability.

The power of Crowning press brake technology:

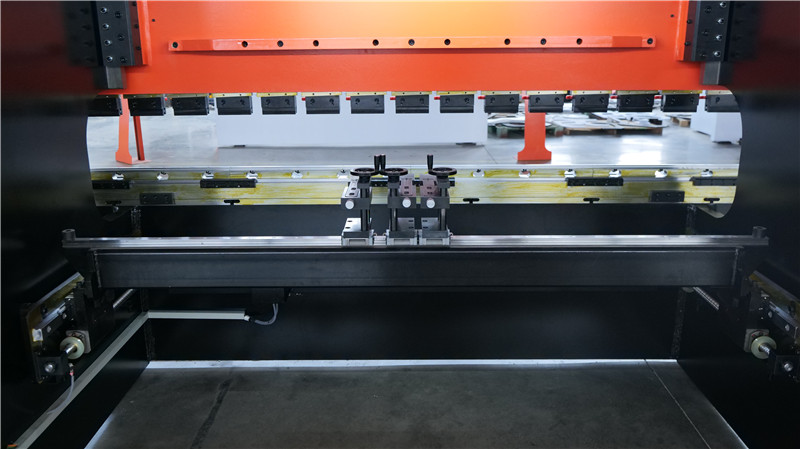

One of the distinguishing features of CNC hydraulic press brakes is their premier press brake technology. This tip mechanism compensates for deflections of the beam and machine bed during bending. The convex press brake feature ensures an even and consistent bend along the entire length of the metal sheet by automatically adjusting the position of the hydraulic clamps. This eliminates any potential inaccuracies caused by material changes or machine deformations, resulting in perfect bends and precise angles.

Precision meets efficiency:

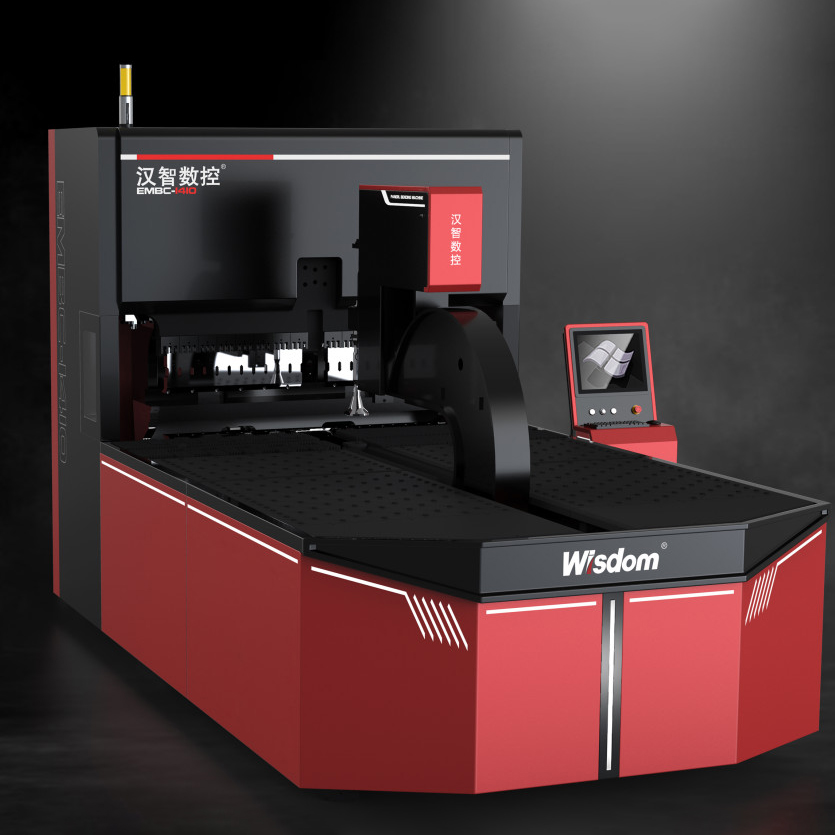

CNC hydraulic press brakes effortlessly combine precision with time efficiency, making them an indispensable tool for modern metal bending. This machine adopts advanced technologies such as automatic angle measurement and multi-axis control, and can complete complex bending accurately and quickly. The CNC system takes care of the calculations, allowing the operator to enter the required parameters and the machine then takes over, ensuring fast, precise bending. The seamless integration of manual input and automated precision significantly reduces production time and increases the overall efficiency of the metal fabrication process.

Unleash the flexibility of metal bending:

CNC hydraulic bending machine is a multi-functional machine capable of bending a variety of metal materials, including aluminum, steel, copper, etc. With its adjustable parameters, operators are free to customize bend radius, angle and width to meet their specific manufacturing requirements. Its adaptability enables the machine to handle both simple and highly complex bending tasks, making it a vital asset to the metalworking industry.

In conclusion: CNC hydraulic bending machines have revolutionized the metal manufacturing industry with their superior functionality and innovative features. This machine utilizes crowning press brake technology to bring precision and consistency to metal bending, ensuring flawless results. The integration of its CNC system and automated controls increases efficiency and reduces production time. Additionally, the flexibility it offers in terms of materials and customization options further cements its status as an indispensable tool for modern metalworking. As the demand for complex and precise metal fabrication continues to grow, CNC hydraulic press brakes remain at the forefront, leading the future of seamless metal bending.

Bending methods include angle bending, absolute value bending and great arc bending.

IInclude upper and lower tool libraries, each library has 50 tools forediting. Program preview and program

Selection functions.

II/O diagnosis function, timely diagnose the problems of the system and equipment.

Workpiece counting function, the counter increases by one every time the program runs

X-axis front limit function, by setting the X-axis front limit in the lower mold parameters.

Pull& move delay function.

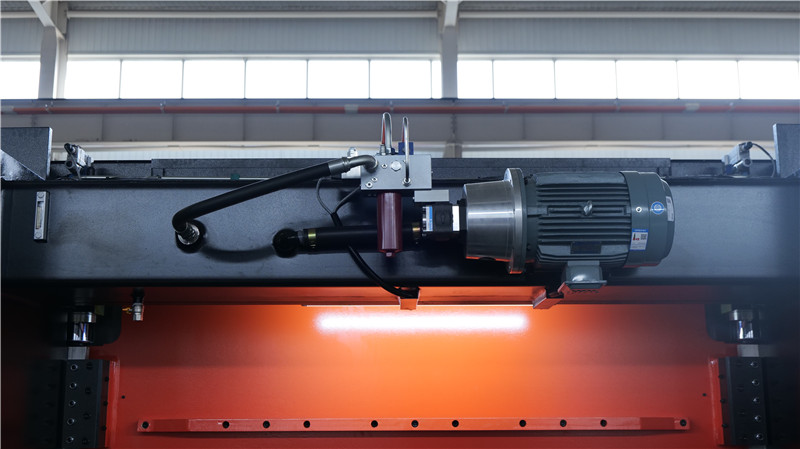

The deflection compensation adopts the mechanical compensation method to improve the stability of the product.

IAutomatic stop function of hydraulic motor, automatic stop in idle time to achieve energy saving effect.

Hydraulic oil replacement reminder function,automatic reminder to replace hydraulic oil after 900 hours of running.

products specification

| Product branda CNC bending machine | Tablelength(mm) 3100mm | |

| Model WSD10031 | Column spacing(mm) 2600mm | |

| Processing capacity 100T | Table heighi 790mm | |

| Numerical contolsystem DELEMLaimore | Throat depth(mm) 400mm | |

| Servo system Fuji | Stroke ofram mm 200mm | |

| Servo motor Fuji | Closed height(mm) | |

| Pressure relief valve group Yuken | Approaching speed(mm/sec) 160 | |

| Magnetic scale GIVI | Working speed(mm/sec) 10 | |

| Hydraulic seal ring NOK(Japan) | Return speed(mm/sec) 130 | |

| Limit switch OMRON[Japan] | Main motor(KW) 7.5KW | |

| Force(KN)1000KN | Weight(KG)8700 | |

| WSD CNC Pressbrake Series specifications Dimension (mm)L*W*H | |||||||||||||

| WSDMode | WSD50/12 | WSD63/25 | WSD100/31 | WSD100/40 | WSD160/32 | WSD160/40 | WSD220/32 | WSD220/40 | WSD250/40 | ||||

| Standaro | Curtain Wallndustry | ||||||||||||

| Force KN | 500 | 630 | 630 | 1000 | 1000 | 1000 | 1000 | 1600 | 1600 | 2200 | 2200 | 2500 | |

| Bending length mm | 1220 | 2500 | 2500 | 3100 | 4000 | 4000 | 4000 | 3200 | 4000 | 3200 | 4000 | 4000 | |

| Column distance mm | 1160 | 2100 | 2100 | 2600 | 3300 | 3300 | 3300 | 2700 | 3300 | 2700 | 3300 | 3300 | |

| Norktable heightmm | 770 | 760 | 760 | 790 | 790 | 790 | 790 | 790 | 790 | 790 | 790 | 810 | |

| Stroke of ram mm | 200 | 150 | 200 | 200 | 200 | 200 | 250 | 200 | 200 | 200 | 200 | 250 | |

| Closed height mm | 410 | 420 | 470 | 470 | 470 | 470 | 520 | 470 | 470 | 470 | 470 | 520 | |

| Throat depthmm | 255 | 250 | 250 | 400 | 400 | 500 | 500 | 400 | 400 | 400 | 400 | 400 | |

| Throat heightmm | 540 | 500 | 500 | 550 | 550 | 550 | 575 | 530 | 530 | 530 | 530 | 570 | |

| Speed of rammm/s | cpproacing | 180 | 130 | 130 | 160 | 160 | 160 | 160 | 130 | 130 | 120 | 120 | 110 |

| working | 15 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 9 | 9 | 9 | |

| retur | 180 | 110 | 110 | 130 | 130 | 130 | 130 | 100 | 100 | 95 | 95 | 95 | |

| -axis strokemm | 500 | 500 | 500 | 500 | 500 | 600 | 500 | 500 | 500 | 500 | 500 | 500 | |

| Bacxgouge posiion irid gode]mm | 900 | 900 | 900 | 900 | 900 | 1000 | 850 | 900 | 900 | 900 | 900 | 900 | |

| Main motor Kw | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 | 11 | 11 | 15 | 15 | 18.5 | |

| 4000 | 4700 | 5700 | 8700 | 9300 | 9500 | 9500 | 11400 | 13400 | 14100 | 15200 | 20000 | ||

| Dimensionmm | L | 1600 | 2690 | 2690 | 3250 | 4080 | 4200 | 4150 | 3360 | 4080 | 3370 | 4080 | 4250 |

| W | 1580 | 1370 | 1370 | 1610 | 2600 | 2000 | 1710 | 1810 | 1810 | 1850 | 1850 | 1850 | |

| H | 2470 | 2570 | 2570 | 2610 | 1570 | 2720 | 2810 | 2720 | 2720 | 2810 | 2810 | 2910 | |

detail show