Improve Efficiency And Precision With CNC Turret Punch Press Machine

products description

The CNC turret punch machine of WSD-S2030NT brand is widely used in the hardware processing industry. It can meet the shape requirements of all different types of materials, and can accurately meet the production requirements in terms of size and quantity. With its excellent performance durability, excellent cutting force capability and fast turnaround time, the punch has become an indispensable member in the list of hardware cutting manufacturers. In addition, the WSD-S2030NT CNC turntable punch machine also has the sensing device necessary to ensure the balance between the torque, displacement, speed and various factors in the processing process of the core part. This equipment is especially suitable for medium and small batch production in all aspects (such as the quantity of 500~1000 pieces in the area of 2.4M * 1.2M on 5mm thick plate). It is convenient to integrate the flow process (such as welding/polishing/loading/unloading/testing/sheet metal cutting/electronic welding), greatly improve the overall production efficiency, make the physical parts appear bright, pleasant and durable, and meet the customer's requirements for the best performance

products specification

| Model and configuration | |||

| Model | WSD30422AI | NC2510NT | WSD—S2030NT |

| CNC system | FANUC Oi—PF | FANUC Oi—PF | Treo,UK |

| Stroke(mm) | 37 | 37 | 32 |

| Positioning precision(mm) | ±0.05 | ±0.05 | ±0.05 |

| Repositioning precision(mm) | ±0.03 | ±0.03 | ±0.03 |

| X-axis stroke(mm) | 2500 | 2500 | 2500 |

| Y-axis stroke(mm | 1250/1500/2000 | 1250/1500/2000 | 1250/1500/2000 |

| Processing sheet size(one positioning)(mm) | 2500*1250/1500/2000 | 2500*1250/1500/2000 | 2500*1250/1500/2000 |

| Max. processing thickness(mm) | 3.2 | 3.2 | 3.2 |

| Maxsheet weight(kg) | 150 | 150 | 150 |

| Max.X-axis moving speed(mmin) | 120 | 120 | 120 |

| Max.Y-axis moving speed(mmin) | 80 | 80 | 80 |

| Max.punch hit at 25mm pace&4mm stroke(hpm | X:360 Y:360 | X:360Y:360 | X:400Y:350 |

| 5mm step 4mm stroke stamping speed(hpm) | 500 | 500 | 500 |

| Maximum punching frequency(cpm) | 920 | 920 | 1900 |

| Maximum punching diameter(mm) | 88.9 | 88.9 | 88.9 |

| Workstation | 42 | 30 | 30 |

| Clamp | 3 | 3 | 3 |

| Number of controllable axes | 5 | 5 | 5 |

| Power requireo | 3 phase 380V50HZ 46KVA | 3 phase 380V50HZ46KVA | 3 phase 380V50HZ 46KVA |

| Overall dimension(I*w*h)mm | 45405200*2160 | 4540*5200*2000 | 6440*5200*2200 |

| Machine weight(ton) | 16 | 14 | 17 |

1. Understanding CNC Turret Punch Presses

CNC Turret Punch Press Machines are advanced automated machines used for precision stamping in various industries including automotive, aerospace, and sheet metal manufacturing. These machines feature a rotating turret that accommodates a variety of tooling options to handle multiple stamping tasks efficiently and quickly.

2. CNC turret punch press machine

The stamping process begins by preparing CAD drawings or design files, which are then converted into machine-readable code using CAM software. After the code is generated, it will be transferred to the CNC turret punch press for execution.

Carefully designed tools within the turret are automatically selected based on the requirements of each stamping task. These tooling options can include various types of punches, dies, and even forming tools, extending the machine's versatility.

The metal sheet or workpiece is firmly clamped on the machine bed, ensuring stability throughout the stamping process. The machine's CNC control system then executes code to precisely move the punch into alignment with the desired location on the workpiece.

The punching tool is activated with great force to accurately punch holes in the workpiece. Depending on the specific requirements, the machine can perform a range of punching actions such as blanking, countersinking or embossing with incredible speed and precision.

3. Advantages of CNC turret punch press

3.1 Precision and Accuracy: CNC turret punch presses offer superior precision for consistent, high-quality results. Advanced control systems ensure precise tool selection, positioning and alignment, reducing errors and minimizing material waste.

3.2 Efficiency and Productivity: By automating the stamping process, CNC turret punch machines significantly increase productivity. The ability to perform various tasks without human intervention saves time and labor costs. Additionally, the ability to switch between different tool options within the turret eliminates the need for manual tool changes, further increasing efficiency.

3.3 Design Flexibility: These machines offer a high degree of design flexibility with the ability to create complex shapes and hole patterns. Design changes can be easily accommodated by simply reprogramming the machine, without the need for physical tooling changes or new setups.

In conclusion:

CNC turret punch presses have revolutionized the stamping process. Their ability to combine precision, efficiency and design flexibility make them an indispensable tool in modern manufacturing. By using these machines, businesses can not only achieve superior quality and productivity but also stay competitive in a rapidly evolving industry. Employing the power of a CNC turret punch press is a smart investment for any company striving for excellence in metal processing and sheet metal fabrication.

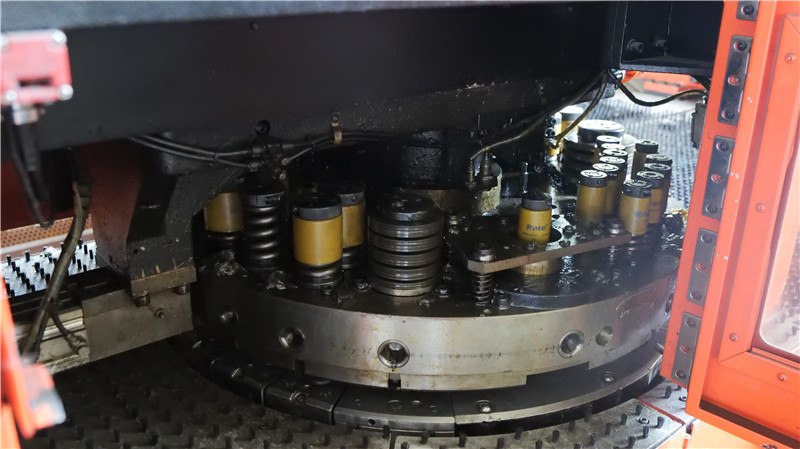

detail show