Improving Accuracy And Efficiency: Exploring The Advantages Of Multi Process Welding Machines

Introduce:

In today's rapidly evolving industrial landscape, welders face the ongoing challenge of adapting to a variety of welding technologies and processes. To meet these needs, welding technology has evolved significantly, paving the way for advanced tools such as multi process welding machines. These innovative devices combine versatility and efficiency to revolutionize the welding industry. In this blog, we’ll take a deep dive into the world of multi-process welding machines, exploring their benefits, applications and how they are shaping the future of welding.

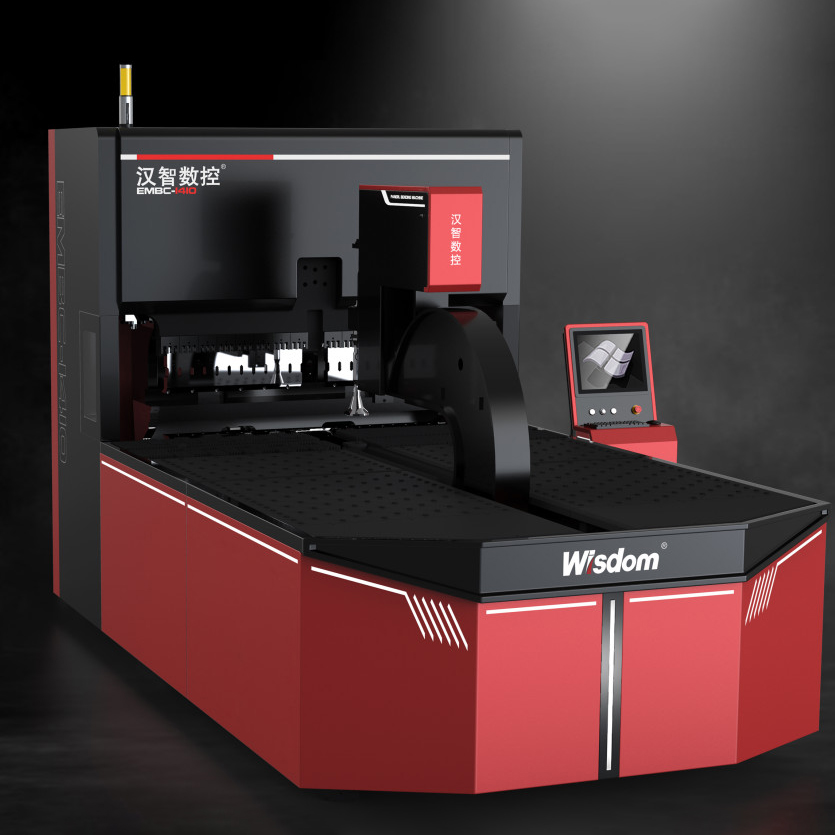

Learn about multi-process welding machines:

A multi process welding machine is a superior piece of equipment that covers a variety of welding techniques, allowing welders to seamlessly transition between different welding processes. These machines eliminate the need for multiple separate pieces of equipment, simplifying the welding process and increasing productivity. They usually integrate functions such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), wire welding and flux-cored welding.

Advantages of multi-process welding machines:

1. Versatility: One of the main advantages of a multi-process welding machine is the ability to handle different welding processes with ease. By combining multiple techniques, welders can complete a wider range of tasks without changing equipment. This versatility meets the different welding needs of the automotive, construction, manufacturing or maintenance industries.

2. Time and cost efficiency: Having a multi-process welding machine can significantly reduce overall equipment investment. Instead of purchasing separate machines for different welding processes, welders can rely on a single piece of equipment. Additionally, the time saved from switching machines and setting up equipment for different processes can increase efficiency and productivity.

3. Space optimization: Multi-process welding machines enable welders to maximize the use of limited work space. Consolidates multiple machines into a compact unit, minimizing the need for storage space, making it ideal for small workshops or job sites with limited space.

4. Improved accuracy: These machines offer adjustable settings that allow welders to fine-tune various parameters such as voltage, current, and wire feed speed. This precision enables skilled welders to produce high-quality welds with greater precision, strength and durability.

In conclusion:

Multi-process welding machines are the ideal companion for the modern welder, offering enhanced versatility, efficiency and precision. As welding technology continues to advance, these machines are shaping the future of welding by enabling professionals to perform various welding processes with ease. From saving time and money to optimizing workspaces and improving weld quality, multi-process welding machines are revolutionizing the welding industry and meeting today's ever-changing needs. So, whether you are an experienced welder or an aspiring hobbyist, embracing these cutting-edge machines will undoubtedly take your welding skills to new heights.

Video

Application

Multi-process welding machines are widely used in various industries, including manufacturing, home construction, shipbuilding, aerospace and automotive industries. Their adaptability provides the flexibility to handle a wide range of materials including steel, aluminum, stainless steel and more. For example, in car repair shops, these machines are used for body repairs and engine component welding. Additionally, multi-process welding machines benefit welding professionals working on different types of projects without having to change equipment.

laser welding machine Precautions for use

1. Wear protective clothing, gloves and glasses when operating the laser welding machine. 2. Please confirm that all parts of the machine are well maintained and in good condition before use. 3. Ensure that the work area is well ventilated to prevent the accumulation of hazardous substances due to welding operations. 4. During the operation of the laser welding machine, please pay attention to potential dangers such as fire, smoke or sparks. 5. Check for loose connections or defective wiring before use, and take necessary precautions if necessary to avoid any electrical shock hazard associated with the machine's power supply or its internal components/circuits. 6. When performing laser welding operations on metals such as steel and aluminum, a safe distance should be kept from flammable substances such as paper and plastic, which are flammable under certain conditions. 7. Do not overheat the material by running pulses that are too long, this can deform the welded part or cause thermal damage to the surrounding area. 8. Take care to discard the hot pieces that come off after the soldering process.

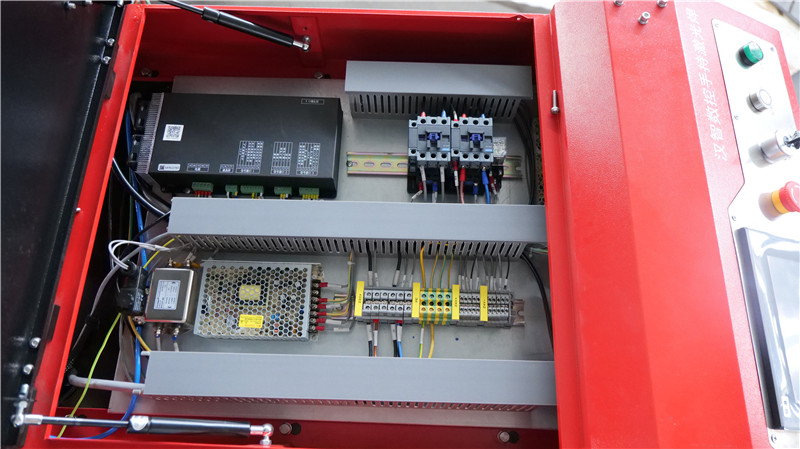

detail show