Revealing The Power And Precision Of CNC Hydraulic Press Brakes

Introduce

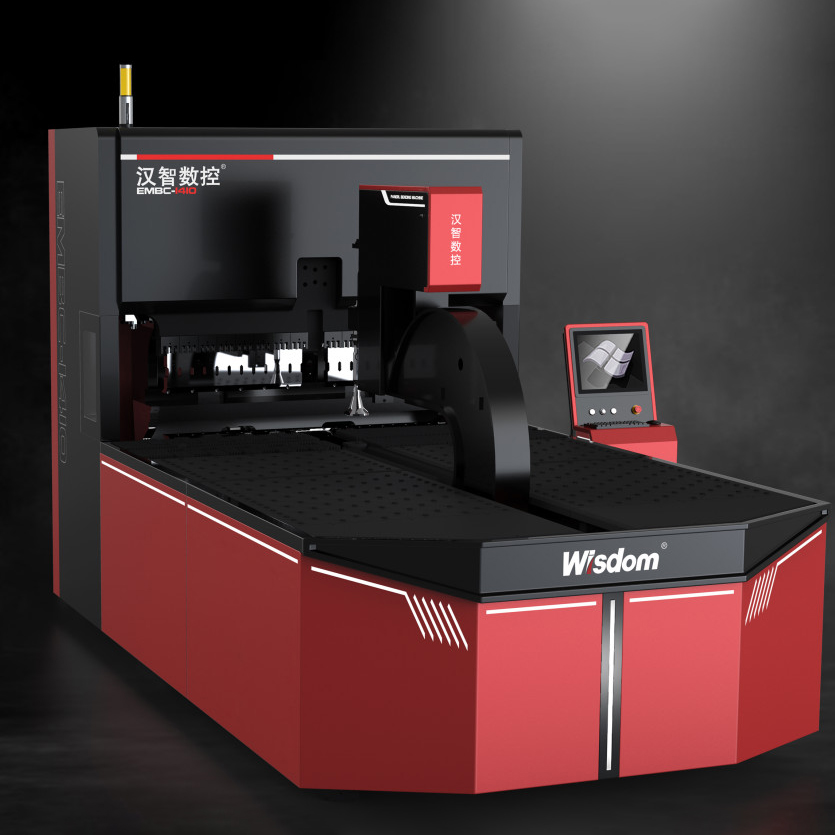

In the field of industrial manufacturing, technological advancements continue to revolutionize the way companies operate. Among these innovations, CNC hydraulic press brakes have become a game changer in the metal fabrication industry. This exceptional machine embodies power, precision and efficiency, delivering significant advantages and raising the bar for metal bending and forming operations. In this blog, we will explore the salient features of CNC hydraulic press brakes, revealing their technical prowess and practical applications.

CNC hydraulic bending machine power

CNC Panel Bending Machines are a force to be reckoned with, possessing extraordinary power to bend and shape various types of metal sheets. Unlike manual equipment, this automated machine utilizes a hydraulic system that exerts tremendous pressure on the metal sheet to create an accurate and consistent bend. By combining hydraulic power with computer numerical control (CNC) technology, operators can achieve precise angles and shapes, eliminating human error and increasing productivity.

Highest accuracy

Precision is an important aspect of metal fabrication. CNC hydraulic press brakes ensure precise results for every operation. This level of accuracy is achieved through the integration of advanced software and programming tools. Operators can input desired bend angles, dimensions and tolerances into the CNC system, allowing the machine to faithfully replicate those specifications without deviation. As a result, metal fabricators can achieve consistent results even in high-volume production environments.

Redefining efficiency

Gone are the days of manual adjustments and time-consuming setup processes. CNC hydraulic press brakes simplify operation and significantly reduce production time and costs. With its user-friendly interface, operators can easily program and automate bending sequences, eliminating the need for manual adjustments to each individual part. In addition, the machine is able to store and recall multiple settings, ensuring fast changeovers between different projects and thus speeding up the production process.

Practical application

CNC hydraulic press brakes find immense use in various industries that require precise metal bending. From automotive to aerospace, the machine caters for a wide range of applications. It can produce parts such as cabinets, construction, electrical enclosures and automotive parts. Whether bending sheet metal into complex shapes or producing uniform components, CNC hydraulic press brakes are versatile solutions trusted by countless manufacturers around the world.

In conclusion

In the ever-evolving field of metal fabrication, CNC hydraulic press brakes are a remarkable testament to human ingenuity and technological innovation. Its superior power, precision and efficiency redefine the standards for metal bending operations, improving productivity and quality across industries. By leveraging the machine’s capabilities, manufacturers can ensure consistent and accurate results to meet rapidly changing market demands. As the world moves towards automation and digitization, CNC hydraulic press brakes are proving to be a vital asset in driving the future of metal manufacturing.