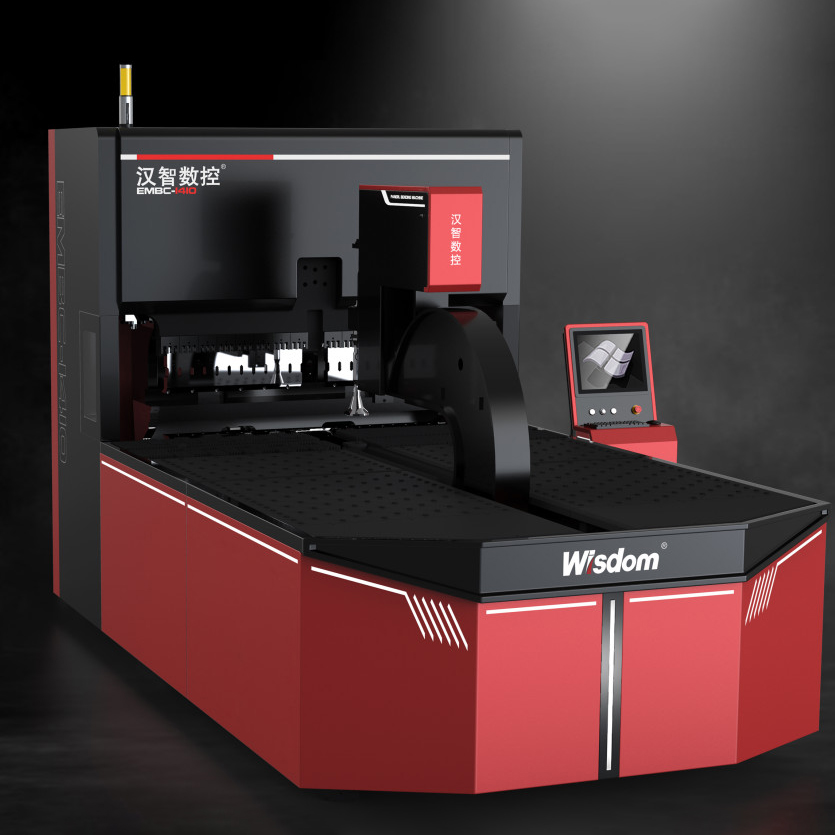

Improving Productivity With Numerical Control Turret Punch Press

Introduce:

In today's manufacturing world, efficiency, precision and speed are key factors in determining a company's success. In order to achieve these goals, various industries continue to explore and adopt advanced technologies to streamline production processes. One of the technologies that is getting a lot of attention is numerical control turret punch press (NCTPP). In this article, we take a deep dive into the world of NCTPP and explore how it is revolutionizing manufacturing.

What is a numerical control turret punch press?

A CNC turret punch press is a machine that combines sheet metal stamping and forming operations into one automated process. The technology is used to create various types of holes, shapes and cuts in sheet metal parts, allowing manufacturers to produce high-quality products quickly and accurately.

products description

Five-axis FANUC (Fanuc) CNC system (including servo motor), precision and stability coexist.

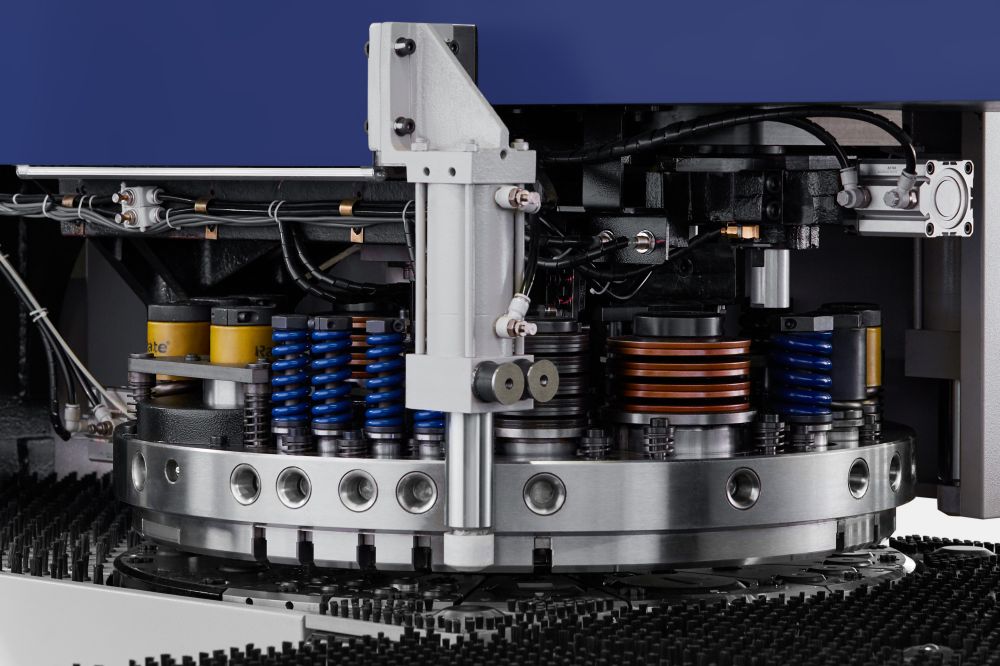

Turret design, imported MAZAK 5-axis machining centers in pairs, to ensure the coaxiality of the work station, guidance and precision.

Double-row workstation design, larger tool transfer volume.

products specification

| Model number NC2510NT | Model number NC2510NT |

| Control system FANUC Oi-PF | 25mm press speed (cpm) 360(4mm stroke) |

| Maximum punching stroke(mm) 37 | 5mm punching speed(cpm) 420(4mm stroke) |

| Positioning accuracy(mm) ±0.05 | Maximum punching diameter(mm) 88.9 |

| Punching accuracy(mm) ±0.1 | Number of stations 30 |

| Repeatability(mm) ±0.03 | Turret speed(rpm) 40 |

| X-axis travel(mm) 2500 | Rotary speed(rpm) 40 |

| Y-axis travel(mm) 1250/1500/2000 | Turret thickness(mm) 95 |

| Size of plate for one-time positioning(mm) 2500*1250/1500/2000 | Number of rotating stations 2 |

| Maximum plate thickness(mm) 3.2 | Clamps 3 |

| Maximum weight of workpiece(kg) 150 | Number of controllable axes 5 |

| Max. travel speed of X-axis (m/min) 100 | Punching method Servomotor drive |

| Max. travel speed of Y-axis(m/min) 80 | Power supply required 3-phase 380V 50HZ46KVA |

| X-axis feeding system Gear, wire bar, reducer | Frame structure 0-type frame |

| Y-axis feeding system Ball screw, silk guide | Overall dimensions (L*W*H)mm 4540*5200*2000 |

| Maximum punching frequency (cpm) 700 | Machine weight (ton) 14 |

detail show

Best accuracy:

One of the main advantages of using numerical control turret punch press is its ability to provide excellent accuracy. The machine operates according to pre-programmed instructions, resulting in consistent accuracy during every manufacturing cycle. Using traditional manual methods, even the most skilled operators are prone to occasional errors or inconsistencies, leading to costly production errors. However, numerical control turret punch press eliminates such risks and ensures that each finished product meets specified design requirements.

Increase productivity:

Traditional stamping and forming methods can be labor-intensive and time-consuming. However, numerical control turret punch press automates these processes, resulting in significant productivity improvements. With the ability to process multiple designs and shapes in a short amount of time, manufacturers are able to meet tight deadlines and satisfy customer needs more efficiently. Additionally, because CNC turret punch press requires minimal human intervention, operators can focus on other important tasks, saving valuable time and resources.

Versatility of operation:

CNC turret punch press proves its versatility by adapting to a variety of sheet metal thicknesses and materials such as steel, aluminum and copper. By providing this flexibility, manufacturers can seamlessly adapt to different requirements and expand their product range. Additionally, CNC turret punch press is capable of performing a variety of operations, including stamping, forming, embossing and threading, providing companies with a competitive advantage in industries as diverse as automotive, electronics and appliances.

Improve cost efficiency:

Implementing CNC turret punch press technology can provide manufacturing companies with significant cost savings. Process automation not only minimizes material waste but also eliminates the additional costs associated with manual labor. In addition, the precise programming of the machines reduces the need for rework and ensures optimal utilization of resources invested in production. As a result, manufacturers using CNC turret punching machine technology can achieve higher profitability while maintaining competitive prices for their products.

In conclusion:

As manufacturing continues to evolve, embracing technological advancements is imperative to stay competitive. CNC turret punch presses are revolutionizing the production process by delivering unrivaled precision, increased productivity, versatility and cost efficiency. Companies that integrate this cutting-edge technology into their operations can streamline their manufacturing processes and meet the changing needs of the market. By staying ahead of the curve, businesses can ensure a prosperous future and achieve exceptional success in their respective industries.