The Evolution of CNC Turret Punch Presses: Revolutionizing Precision and Efficiency

products description

Introduce:

In industrial manufacturing, efficiency and precision are keys to success. Over the years, technological advancements have played a key role in transforming manufacturing. One such innovation is the CNC Turret Punch Press (NCTPP), which has transformed the sheet metal manufacturing process. With its ability to streamline production processes while ensuring the highest accuracy, NCTPP has become an integral part of various industries. In this blog, we’ll delve into the evolution of NCTPP and explore its impact on modern manufacturing.

The emergence of CNC turret punch press:

The concept of numerical control (NC) in machining can be traced back to the mid-20th century. Manual operation of machines was gradually replaced by computer-controlled automation, allowing for greater precision and repeatability. Turret punch presses, used to punch holes in sheet metal, were among the first machines to use CNC technology. This marked the birth of the CNC turret punch press.

products specification

| Model and configuration | |||

| Model | WSD30422AI | NC2510NT | WSD—S2030NT |

| CNC system | FANUC Oi—PF | FANUC Oi—PF | Treo,UK |

| Stroke(mm) | 37 | 37 | 32 |

| Positioning precision(mm) | ±0.05 | ±0.05 | ±0.05 |

| Repositioning precision(mm) | ±0.03 | ±0.03 | ±0.03 |

| X-axis stroke(mm) | 2500 | 2500 | 2500 |

| Y-axis stroke(mm | 1250/1500/2000 | 1250/1500/2000 | 1250/1500/2000 |

| Processing sheet size(one positioning)(mm) | 2500*1250/1500/2000 | 2500*1250/1500/2000 | 2500*1250/1500/2000 |

| Max. processing thickness(mm) | 3.2 | 3.2 | 3.2 |

| Maxsheet weight(kg) | 150 | 150 | 150 |

| Max.X-axis moving speed(mmin) | 120 | 120 | 120 |

| Max.Y-axis moving speed(mmin) | 80 | 80 | 80 |

| Max.punch hit at 25mm pace&4mm stroke(hpm | X:360 Y:360 | X:360Y:360 | X:400Y:350 |

| 5mm step 4mm stroke stamping speed(hpm) | 500 | 500 | 500 |

| Maximum punching frequency(cpm) | 920 | 920 | 1900 |

| Maximum punching diameter(mm) | 88.9 | 88.9 | 88.9 |

| Workstation | 42 | 30 | 30 |

| Clamp | 3 | 3 | 3 |

| Number of controllable axes | 5 | 5 | 5 |

| Power requireo | 3 phase 380V50HZ 46KVA | 3 phase 380V50HZ46KVA | 3 phase 380V50HZ 46KVA |

| Overall dimension(I*w*h)mm | 45405200*2160 | 4540*5200*2000 | 6440*5200*2200 |

| Machine weight(ton) | 16 | 14 | 17 |

Unleash precision and versatility:

With the integration of computer control, Numerical Control Turret Punch Press becomes highly accurate and efficient. Sophisticated software programs allow operators to create complex designs and patterns, which are then executed flawlessly and quickly by machines. The ability to manipulate programmable tools within the turret spindle enables a variety of operations, including drilling, forming, tapping, and even laser cutting. This versatility eliminates the need for additional machines, reducing costs and production time.

Improve productivity and cost-effectiveness:

The advent of NCTPP has significantly improved manufacturing productivity. By reducing manual labor, these machines can operate continuously, minimizing downtime and maximizing production. Additionally, the automation provided by NCTPP eliminates errors and waste, allowing for cost-effective production. Jobs that once required hours of manual labor can now be completed in minutes, with greater precision and consistency.

Seamless integration of CAD/CAM systems:

The integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems with NCTPP has further transformed the sheet metal manufacturing process. CAD software helps create complex designs, which can then be seamlessly imported into CAM software to generate tool paths. These paths, when fed into NCTPP, guide machines to perform precise operations without human intervention, ensuring consistency and accuracy.

Advances in automation:

As manufacturing needs continue to grow, NCTPP's growth does not stop. The introduction of robotic arms and automatic paper feeding systems revolutionized the efficiency and productivity of these machines. Robots can easily load and unload plates, reducing labor and increasing production speed. These automation advances have transformed NCTPP into an efficient, autonomous manufacturing system.

In conclusion:

The evolution of CNC turret punch presses has undoubtedly reshaped manufacturing. Its integration of computer control, precision, versatility and automation takes the sheet metal manufacturing process to new heights. Manufacturers can now efficiently meet growing demand while maintaining high levels of accuracy and consistency. As technology continues to advance, it is exciting to imagine the future enhancements that NCTPP will bring to the industrial manufacturing sector.

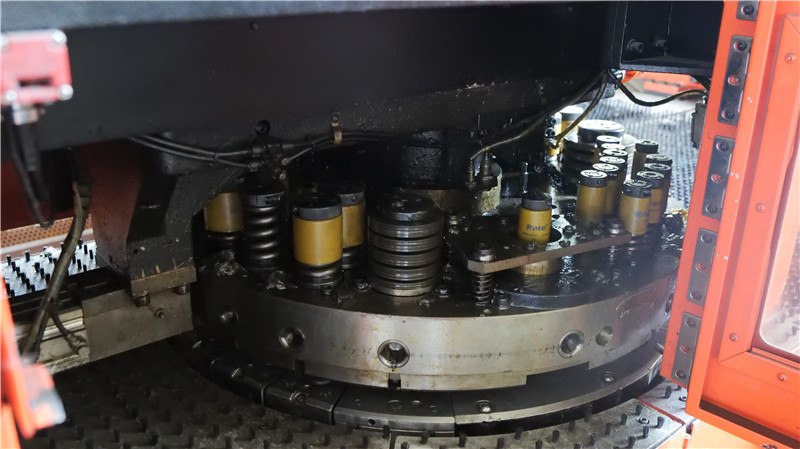

detail show