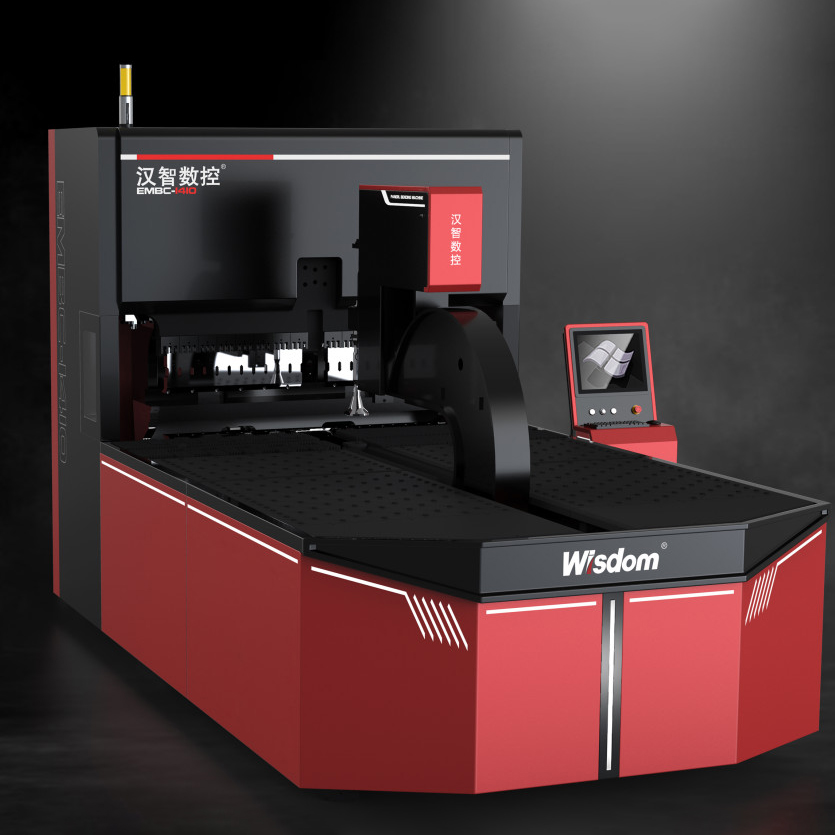

CNC Turret Punch Machine

products description

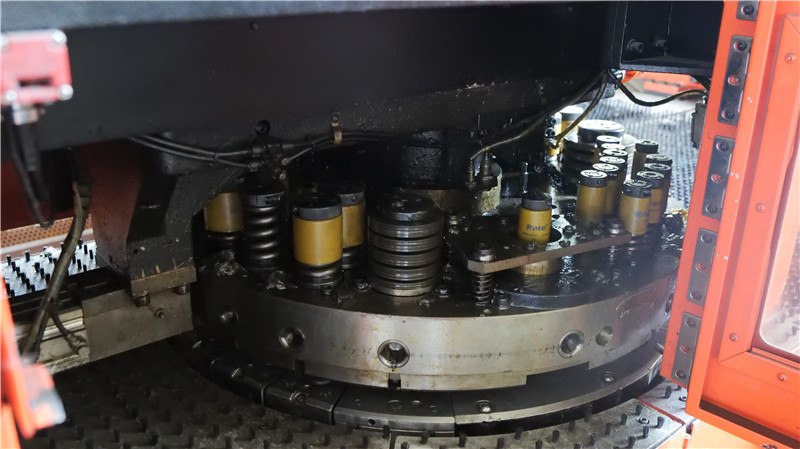

The CNC turret punch machine of WSD-S2030NT brand is widely used in the hardware processing industry. It can meet the shape requirements of all different types of materials, and can accurately meet the production requirements in terms of size and quantity. With its excellent performance durability, excellent cutting force capability and fast turnaround time, the punch has become an indispensable member in the list of hardware cutting manufacturers. In addition, the WSD-S2030NT CNC turntable punch machine also has the sensing device necessary to ensure the balance between the torque, displacement, speed and various factors in the processing process of the core part. This equipment is especially suitable for medium and small batch production in all aspects (such as the quantity of 500~1000 pieces in the area of 2.4M * 1.2M on 5mm thick plate). It is convenient to integrate the flow process (such as welding/polishing/loading/unloading/testing/sheet metal cutting/electronic welding), greatly improve the overall production efficiency, make the physical parts appear bright, pleasant and durable, and meet the customer's requirements for the best performance

products specification

| Model and configuration | |||

| Model | WSD30422AI | NC2510NT | WSD—S2030NT |

| CNC system | FANUC Oi—PF | FANUC Oi—PF | Treo,UK |

| Stroke(mm) | 37 | 37 | 32 |

| Positioning precision(mm) | ±0.05 | ±0.05 | ±0.05 |

| Repositioning precision(mm) | ±0.03 | ±0.03 | ±0.03 |

| X-axis stroke(mm) | 2500 | 2500 | 2500 |

| Y-axis stroke(mm | 1250/1500/2000 | 1250/1500/2000 | 1250/1500/2000 |

| Processing sheet size(one positioning)(mm) | 2500*1250/1500/2000 | 2500*1250/1500/2000 | 2500*1250/1500/2000 |

| Max. processing thickness(mm) | 3.2 | 3.2 | 3.2 |

| Maxsheet weight(kg) | 150 | 150 | 150 |

| Max.X-axis moving speed(mmin) | 120 | 120 | 120 |

| Max.Y-axis moving speed(mmin) | 80 | 80 | 80 |

| Max.punch hit at 25mm pace&4mm stroke(hpm | X:360 Y:360 | X:360Y:360 | X:400Y:350 |

| 5mm step 4mm stroke stamping speed(hpm) | 500 | 500 | 500 |

| Maximum punching frequency(cpm) | 920 | 920 | 1900 |

| Maximum punching diameter(mm) | 88.9 | 88.9 | 88.9 |

| Workstation | 42 | 30 | 30 |

| Clamp | 3 | 3 | 3 |

| Number of controllable axes | 5 | 5 | 5 |

| Power requireo | 3 phase 380V50HZ 46KVA | 3 phase 380V50HZ46KVA | 3 phase 380V50HZ 46KVA |

| Overall dimension(I*w*h)mm | 45405200*2160 | 4540*5200*2000 | 6440*5200*2200 |

| Machine weight(ton) | 16 | 14 | 17 |

detail show