Electric Servo Bending Machine Quotation-HPE 6020

Main Specification

|

No. |

Name |

Parameter |

Unit |

|

|

1 |

Bending force |

600 |

KN |

|

|

2 |

Bending length |

2000 |

mm |

|

|

3 |

Ram stroke |

1800 |

mm |

|

|

4 |

Throat depth |

250 |

mm |

|

|

5 |

Throat height |

500 |

mm |

|

|

6 |

Height of worktable |

760 |

mm |

|

|

7 |

Bending speed |

50 |

mm/sec |

|

|

8 |

Air speed |

200 |

mm/sec |

|

|

9 |

Return speed |

200 |

mm/sec |

|

|

10 |

X axis |

Stroke |

500 |

mm |

|

11 |

speed |

250 |

mm/sec |

|

|

12 |

R axis |

Stroke |

250 |

mm |

|

13 |

speed |

120 |

mm/sec |

|

|

15 |

X-axis positioning accuracy |

±0.02 |

mm |

|

|

16 |

Weight |

4800 |

Kg |

|

|

17 |

Size |

2190x2500x2280 |

mm |

|

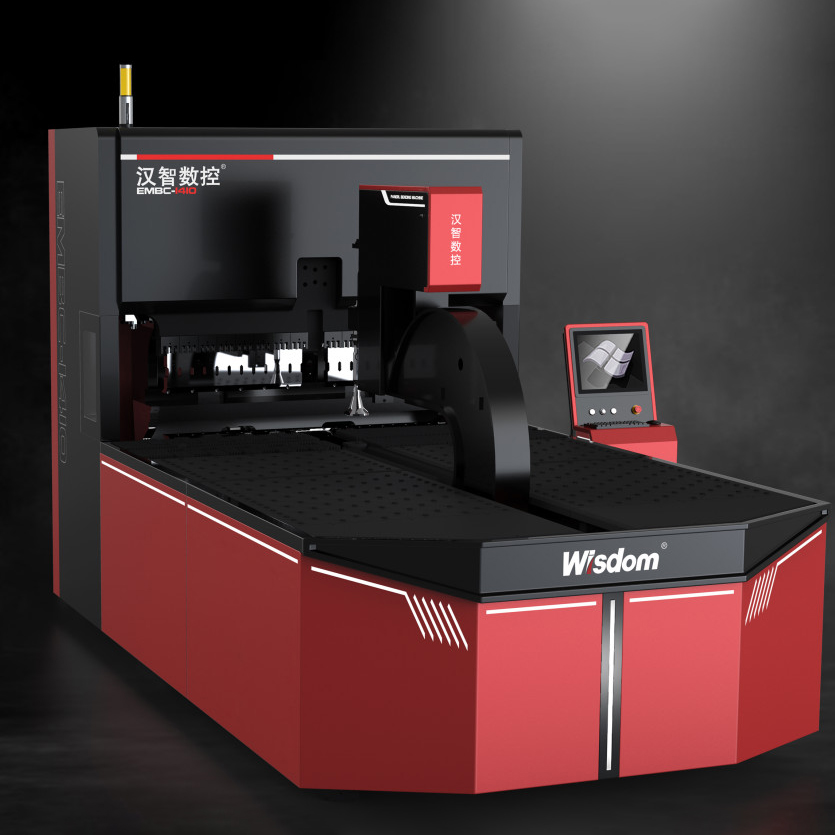

Main structure and features

Hebei Hanzhi CNC Machinery Co., Ltd. mainly focuses on the following points in equipment design and manufacturing:

l Pursue practicality and save every penny for the market concept of users;

l Very reliable and sophisticated design ideas;

l High-quality raw materials, outsourced parts and exquisite processing technology;

l More emphasis on the convenience and safety of use and maintenance;

l Low maintenance rate and maintenance use cost in the same industry.

This machine tool is mainly composed of frame, slider, rear blocking system, control system and mold, etc.

1.Frame: This part consists of left and right columns, support plate, lower table and other components of the frame frame. The bed is made of steel plate welded as a whole, after welding, the implementation of 700 degrees 24 hours high-temperature aging, surface shot blasting treatment, completely eliminating the internal stress generated during welding, the use of heavy-duty design to ensure the rigidity and long-term stability of the machine tool.

2.Slider : This part mainly consists of slider, power box, magnetic scale, screw, rectangular guide rail vice and so on. Left and right power box with bolts and frame fastening connection, screw and slider using nuts, ball block connection, the structure of the slider in the bearing bias load can improve the live. The slider and

the frame are connected by rectangular guide rail. The guide rail is self-lubricating, and only a few drops of oil are needed every week. In the frame on both sides of the C-shaped plate is equipped with a scale, to control the upper limit of the slider stroke position, the lower limit of the position, the empty stroke and the working stroke shift point position, as well as detection, the two screws synchronized movement status.

3. Control system: Adopting self-developed numerical control system, automatic calculation of bending force according to plate thickness material and length, automatic calculation of angle error correction.

4. Mold: This part consists of two parts: the upper mold assembly and the lower mold assembly. The upper mold is mounted on the slider, relying on the clamping plate to fix it, the lower mold can be in the form of single V, double V and multi-V, etc. The mold can be segmented according to the user's requirements.

5. Front pallet holder: This part is a standard part and is mounted on the front of the table. When in use, according to the length of the workpiece, the front pallet holder can be moved manually to the appropriate position for fastening, the pallet holder can be adjusted horizontally and vertically.

Product Structure

1. Hanzhi independent design, beautiful appearance, well-made.

2. Overall steel plate welding structure, thick frame, rigidity and shock absorption.

3. The structural parts are descaled by sanding and sprayed with antirust paint.

4. The column, upper working slide and lower table of the machine tool are finely machined by the world's top large-scale CNC floor boring and milling machine, which ensures the parallelism, perpendicularity and parallelism of each mounting surface.

5. The upward dynamic bending design is smooth, easy and safe to operate.

6. In the lower dead center, there is the function of pressure preservation delay to ensure the precision of the workpiece.

7. Under the conditions of national or international standards, the bending angle accuracy is ensured within ± 0.5 degrees.

The machine is designed using finite element analysis

3、Machine characteristics

The screw stroke is 150mm and the throat depth is 150mm, which greatly improves the processing range of product parts.

4、Electrical Control System

1. The electrical components are in line with international standards, safe and reliable, with strong anti-interference ability, and the electric control cabinet has heat dissipation function.

2. With movable foot switch operation and emergency stop function.

3. Most of the electrical components adopt domestic first-class brand products.