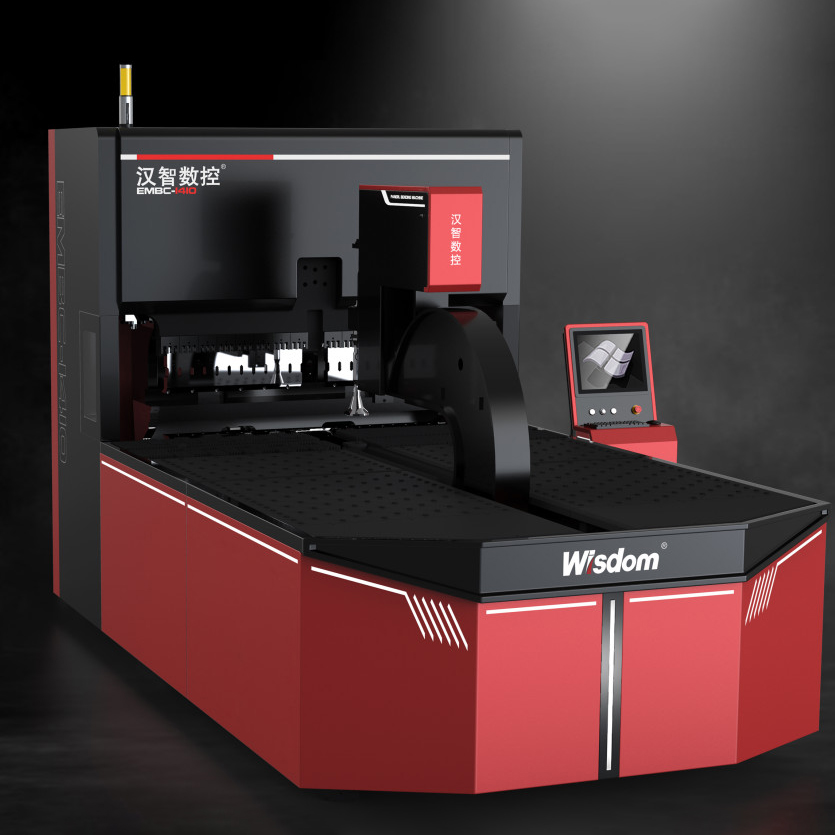

Automatic Panel Bender HMBC2202-2203

products specification

| No. | Name | Parameter | Unit |

| 1 | Max.length | 2200 | mm |

| 2 | Max.width | 1500 | mm |

| 3 | Min. Bending length | 130 | mm |

| 4 | Min.bending width | 240 | mm |

| 5 | Max.bending thickness ( MS , UTS410N/mm² ) | 2 | mm |

| 6 | Min.bending thickness ( MS , UTS410N/mm² ) | 0.35 | mm |

| 7 | Max.bending height | 200 | mm |

| 8 | Length adjustment mode of upper press | Automatic | |

| 9 | Average energy consumption | 4 | KW |

| 1 0 | Outlook size : L*W*h | 6100 * 2700 * 2920 | mm |

products specification

| No. | Name | Parameter | Unit |

| 1 | Max.length | 2200 | mm |

| 2 | Max.width | 1500 | mm |

| 3 | Min. Bending length | 430 | mm |

| 4 | Min.bending width | 350 | mm |

| 5 | Max.bending thickness ( Stainless steel , UTS660N/mm ) | 1.8(+-90 ° ) | mm |

| 6 | Max.bending thickness ( steel,UTS410N/mm ) | 3(+-90 ° ) | mm |

| 8 | Min.bending thickness ( aluminium , UTS120N/mm ) | 0.35 | mm |

| 9 | Max.bending height | 300 | mm |

| 10 | Length adjustment mode of upper press | Automatic | |

| 11 | Average energy consumption | 12 | KW |

| 12 | Weight | 32 | T |

| 13 | Outlook size : L*W*h | 6300*5500*3300 | mm |

Characteristics and main structure

In terms of machine design and manufacturing, He Bei Han Zhin CNC Machinery Co.,Ltd. mainly focuses on the following points:

1.The market concept of pursuing practicality and saving every penny for users;

2.Very reliable and precise design ideas;

3.High quality raw materials, outsourced parts and exquisite processing technology;

4.More emphasis on the convenience and safety of use and maintenance;

5.Low maintenance rate and maintenance cost in the same industry.

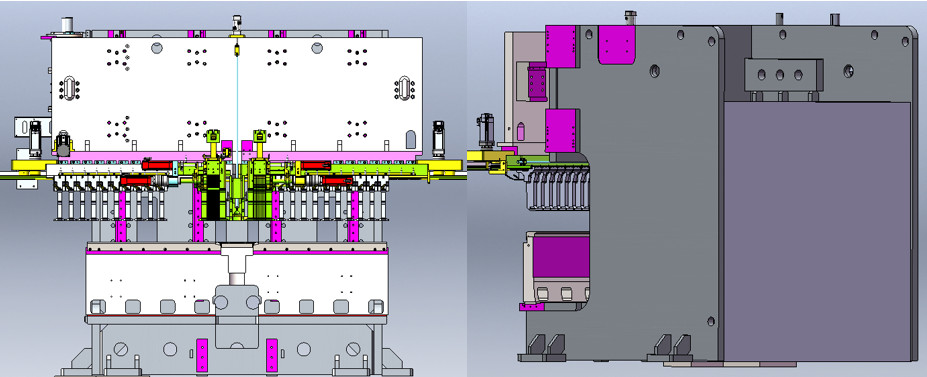

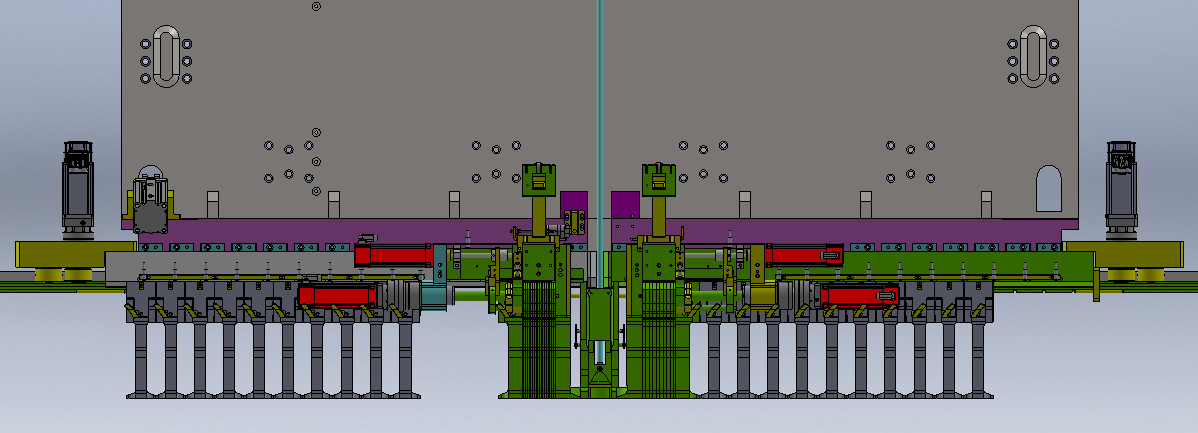

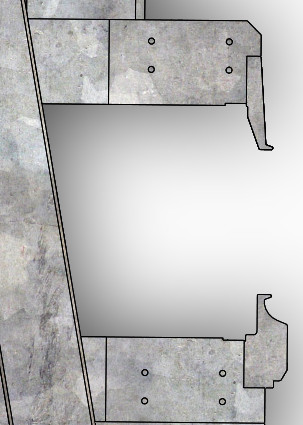

frame

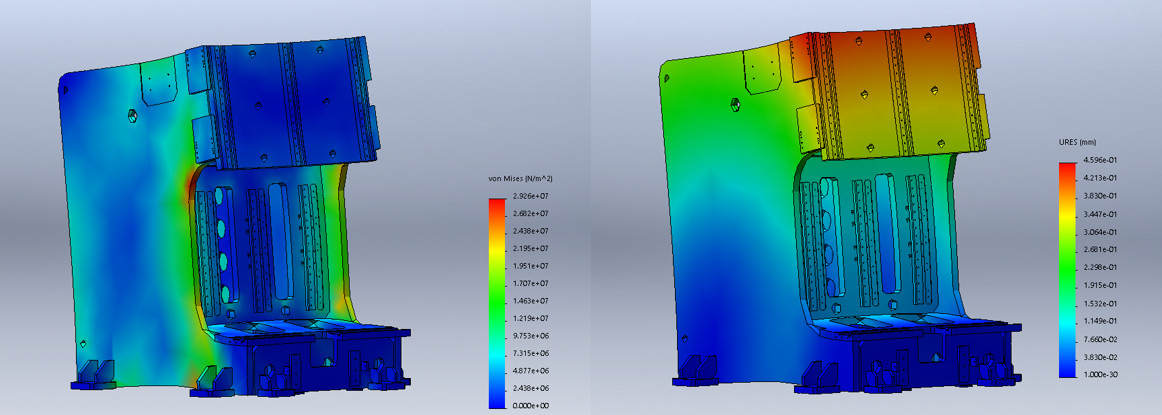

A. Establish three-dimensional finite element model: according to the three-dimensional solid model developed and designed, establish the finite element dynamic model for calculation. The model considers the main components on the force transmission connection. The force is transmitted to the support through the connecting parts, and then the strength analysis of the support is carried out.

B. Analysis of static analysis results: due to the slow processing speed, the strength analysis can be attributed to static problems. According to the plate pressing load and the bending load in the vertical direction of the cutter head, the stress and deformation results are shown in the figure below. The maximum stress appears at the throat of the fuselage, the maximum stress is 21.2mpa, the maximum deformation appears at the upper end of the fuselage, and the maximum deformation is 0.30mm.

According to the results of finite element analysis of the frame, Q345 steel is selected as the material; Carbon dioxide shielded welding; Conduct tempering treatment to eliminate the stress caused by welding; So as to ensure the accuracy, stability and high rigidity of the equipment for long-term operation.

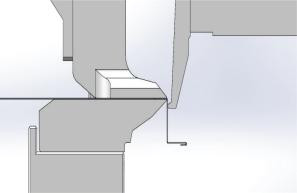

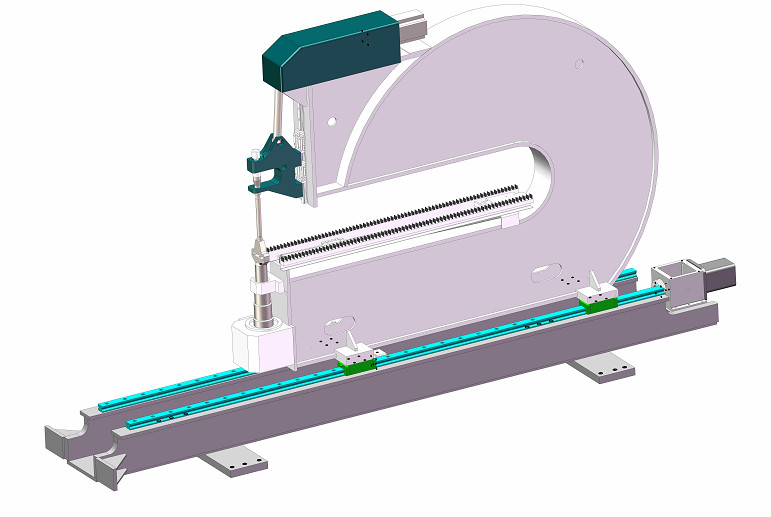

Upper ram

This part is mainly composed of ram, high torque lead screw, reducer, guide rail, servo motor, etc. The main drive is controlled by servo motor, and the control mode is servo synchronous control, which can effectively ensure the positioning accuracy, fast speed and high controllability. The lubrication of the lead screw and guide rail adopts automatic lubrication, and the grease is 00#, so as to ensure the service life and accuracy of the lead screw and guide rail for long-time operation.

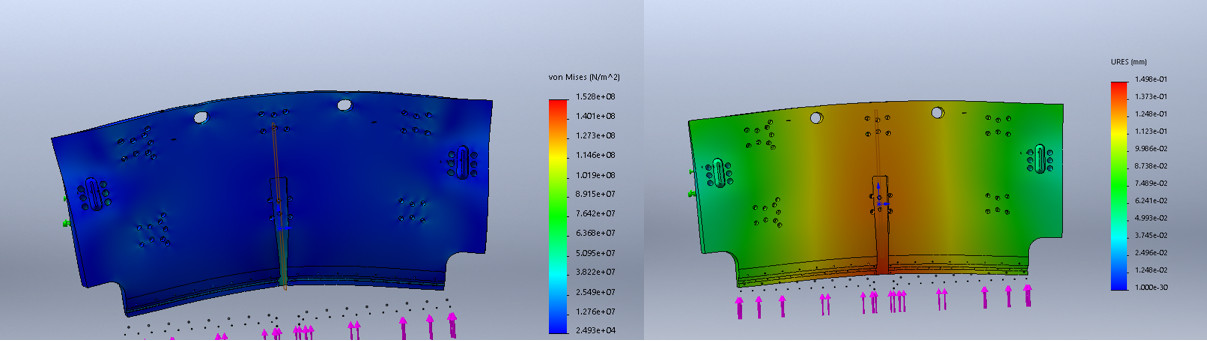

Analysis of the static analysis results of the upper slider: the stress displacement nephogram of the upper worktable shows that the maximum stress appears at the top of the upper part, the maximum stress is 152mpa, the maximum deformation appears at the upper end of the upper worktable, and the maximum deformation is 0.15mm

According to the results of finite element analysis of the ram, Q345 steel is selected as the material; Carbon dioxide shielded welding; Conduct tempering treatment to eliminate the stress caused by welding; So as to ensure the accuracy, stability and high rigidity of the equipment for long-term operation.

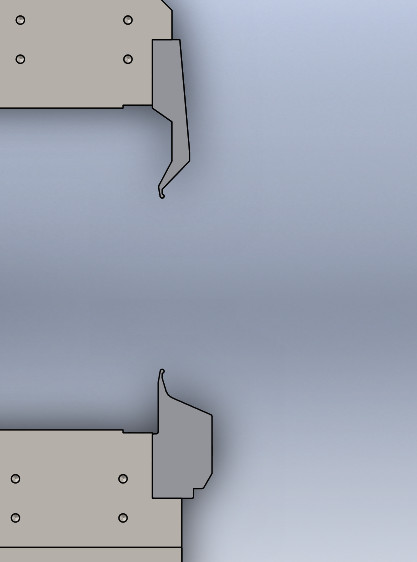

Bending unit

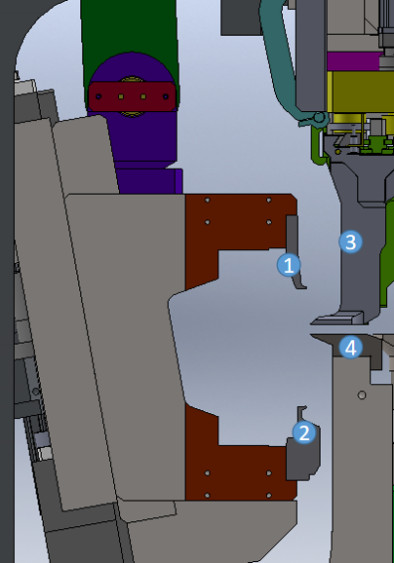

The power driving part of the bending unit is driven by servo motor without the participation of hydraulic system, which has great advantages in reducing component wear and transmission efficiency, and is in line with the energy-saving and environmental protection policy advocated by the state.

According to the setting of plate information, the system automatically calculates the position of upper pressing knife 3, controls the distance between upper pressing knife 3 and lower pressing knife 4, and fixes the plate; According to the system setting, whether this bending is upward or downward, control the lower bending knife 2 or the upper bending knife 1 to move quickly to the bending position; According to the different setting angles, the patented angle calculation formula controls the bending punch to move to the calculation position to complete the bending.

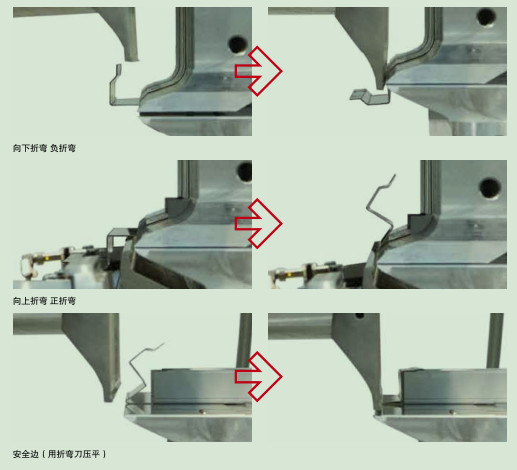

According to different bending methods, it can be divided into angle bending, large arc bending, flattening bending, etc. among them, angle bending is also divided into upward bending and downward bending.

Upper press unit

Upper pressing unit: a part to be used in all bending processing. HMBC full servo multilateral bending center is equipped with a special upper press unit, which can be installed and adjusted automatically according to different plate lengths.

Tool

Bending tools are divided into upper bending tools and lower bending tools. Special bending tools can be customized according to different requirements of customers.

2.Plate feeding unit:

The movement, clamping and rotation of sheet metal are controlled by manipulator 1, clamp 2 and rotating disc 3 respectively. The feeding of sheet metal is controlled by servo motor in the whole processing process, so as to realize automation and rapid positioning, reduce action time and improve efficiency. Due to the innovation of structure and the application of full servo control, in the whole working process of multilateral bending center, the clamping and rotation of sheet metal can maintain accuracy. For many complex workpieces and even polygonal workpieces, the continuous rotation accuracy can be guaranteed to be 0.001.

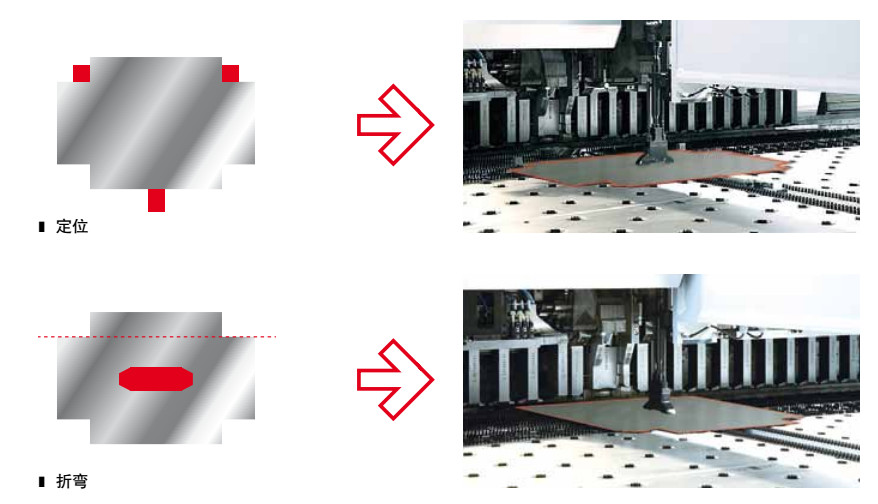

3.Plate positioning unit :

The plate positioning unit is composed of left positioning pin, right positioning pin, front positioning pin and rear positioning pin; The left and right positioning pins can locate the left and right positions of the plate. The front positioning pin and the rear positioning pin control the front and rear positions of the plate to ensure that the plate is parallel to the upper and lower pressing knives, which is used to ensure the positioning accuracy of the plate.

The plate positioning unit can complete the automatic positioning of the plate and automatically complete the multilateral bending at one time, which greatly shortens the bending cycle time and controls the shearing error of the plate on the first bending to ensure the accuracy of the bending.

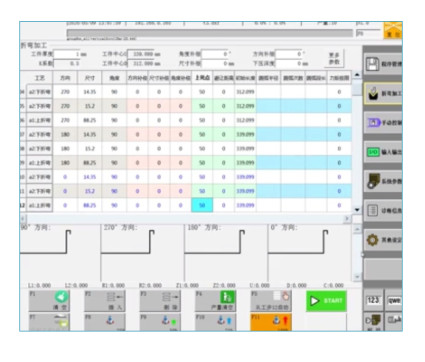

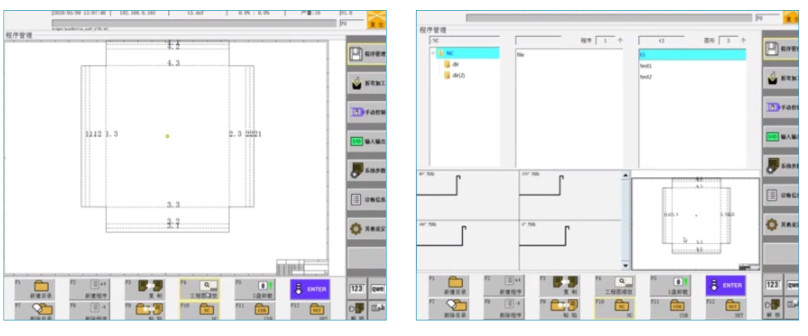

4.CNC system

A: The CNC system and software developed jointly can be applied and managed quickly and conveniently

B: Main features:

a) . EtherCAT bus control mode is adopted, with strong anti-interference ability

b) Support direct programming and input bending data of each step in the form

c) Support arc bending

d) Full electric servo control

e) Support bending compensation function

f) Support two-dimensional programming function

Two dimensional programming function, import two-dimensional DXF drawing data, and automatically generate bending process, bending size, bending angle, rotation angle and other data. After confirmation, automatic bending processing can be carried out

List of main part

| No. | Name | Brand |

| 1 | Frame | Wisdom |

| 2 | Tool | Wisdom |

| 3 | Bending unit | Wisdom |

| 4 | CNC System | Wisdom |

| 5 | Servo motor | Wisdom |

| 6 | Servo driver | Wisdom |

| 7 | Rail | Wisdom |

| 8 | Ballscrew | Wisdom |

| 9 | Reducer | Taiwan |

| 10 | Breaker | Schneider |

| 11 | Button | Schneider |

| 12 | Electrical part | Schneider |

| 13 | Cable | Yicu |

| 14 | Proximity switch | Omron |

| 15 | Bearing | SKF/NSK/NAICH |

4)The design, manufacture, inspection and installation of the machine tool meet the following standards.

1、GB17120-1997

2、Q/321088JWB19-2012

3、GB14349-2011

Spare part and tool list

| No. | Name | Qt. | Remark |

| 1 | Tool box | 1 | |

| 2 | Install pad | 8 | |

| 3 | Inner hexagon spanner | 1 set | |

| 4 | Manual refueling gun | 1 | |

| 5 | CNC system manual | 1 | |

| 6 | open spanner | 1 |