When it comes to metal fabrication, precision is key. An important aspect of metal bending is the bend radius. Understanding the bending radius of your panel bending machine is critical to obtaining accurate and high-quality results. In this blog, we’ll dive into the importance of bend radius and its impact on panel flex.

Bend radius is a measure of how tightly a bend can be made in a piece of metal without causing deformation or damage to the material. In panel bending, the bend radius plays a vital role in determining the overall quality and structural integrity of the bent metal. Specified bend radii must be adhered to to ensure the final product meets the required specifications and standards.

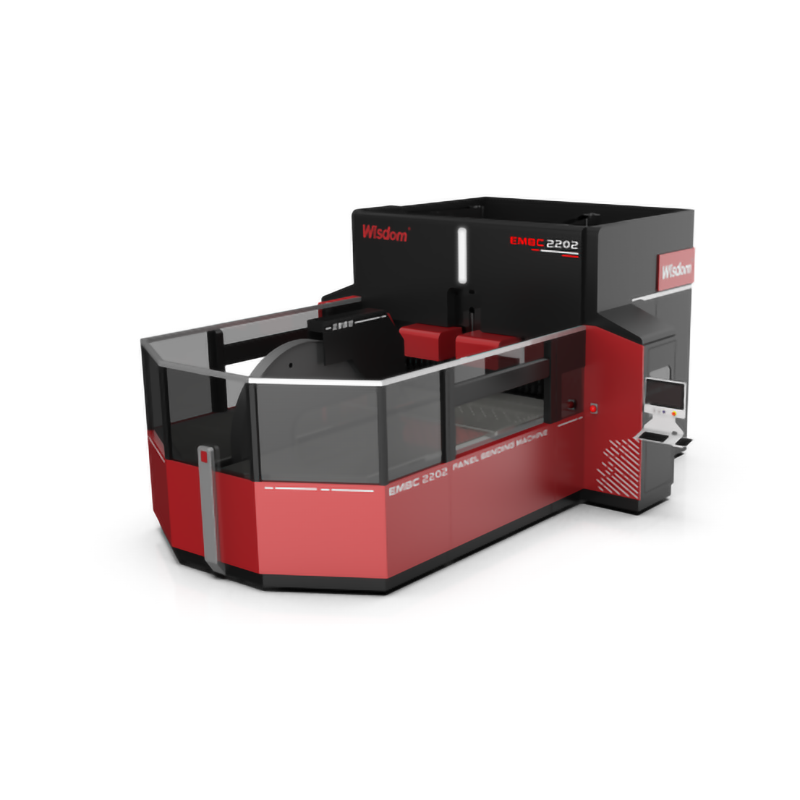

Plate bending machines are used to bend metal sheets into various shapes and angles. The accuracy of the bending radius directly affects the bending accuracy and consistency of the plate bending machine. By understanding and controlling the bend radius, manufacturers can ensure that the metal sheet is bent without any distortion, cracks, or wrinkles, resulting in a perfect final product.

Additionally, the bend radius determines the minimum radius that can be achieved during the bending process. This is critical for applications requiring tight tolerances and specific geometric requirements. By precisely controlling the bend radius, manufacturers can achieve precise bends that meet the precise specifications of the design, thereby improving the overall quality and performance of manufactured metal parts.

In addition to ensuring bending quality, understanding and optimizing the bending radius of your panel bending machine can improve efficiency and cost-effectiveness. By utilizing proper bend radii, manufacturers can minimize material waste and reduce the need for secondary operations, ultimately saving time and resources during the production process.

In addition, the bending radius directly affects the mechanical properties of the bent metal. Incorrect bend radii can cause stress concentrations and weaken the structural integrity of the metal, potentially compromising the functionality and durability of the final product. By adhering to recommended bend radii, manufacturers can maintain the mechanical strength and performance of curved components, ensuring their reliability in real-world applications.

To achieve precise and consistent bend radii on panel bending machines, manufacturers can leverage advanced technology and software systems to monitor and control the bending process in real time. These tools enable operators to accurately set and maintain the desired bend radius, resulting in high-quality, repeatable bends with minimal deviation.

In summary, the bend radius on panel bender is a critical parameter that has a significant impact on the quality, accuracy and performance of bent metal parts. By understanding the importance of bend radius and its impact on panel bending, manufacturers can optimize their bending processes to achieve superior results that meet the highest standards of excellence in metal manufacturing. Adhering to the specified bend radius is critical to ensuring the structural integrity, dimensional accuracy and mechanical strength of the bent metal, which ultimately contributes to the overall success and reliability of the manufactured product.

Post time: Dec-15-2023