In the world of precision engineering and metalworking, few machines can match the versatility and efficiency of sheet metal bending machines. These advanced machines revolutionized the manufacturing industry by delivering unparalleled precision, speed and accuracy in bending and forming sheet metal. From small components to large building structures, sheet metal bending machines have become an indispensable tool for manufacturers around the world.

Sheet metal bending machines are at the forefront of modern manufacturing, allowing companies to meet the growing demand for complex and precise designs. Designed to bend and shape sheet metal with ease, these machines utilize innovative technology and advanced features to ensure optimal results. Sheet metal bending machines are capable of bending a variety of metals, including steel, aluminum, copper, and even high-strength alloys, offering a wide range of possibilities for different industries.

One of the key advancements in sheet metal bending machine is the integration of computer numerical control (CNC) technology. This sophisticated control system allows manufacturers to program precise bending sequences, angles and dimensions to produce consistent and accurate parts. By eliminating the need for manual adjustments, CNC sheet metal bending machines can significantly reduce human error, increase production speeds and improve overall efficiency. This automation has revolutionized the manufacturing process, allowing manufacturers to efficiently deliver complex, customized products.

Another notable feature of sheet metal bending machine is their ability to handle multiple bends in a single operation. This not only saves time and increases productivity, but also ensures consistency in the production process. Whether it’s a simple 90-degree bend or a complex series of bends, sheet metal panel bending machines can handle the task with precision and consistency.

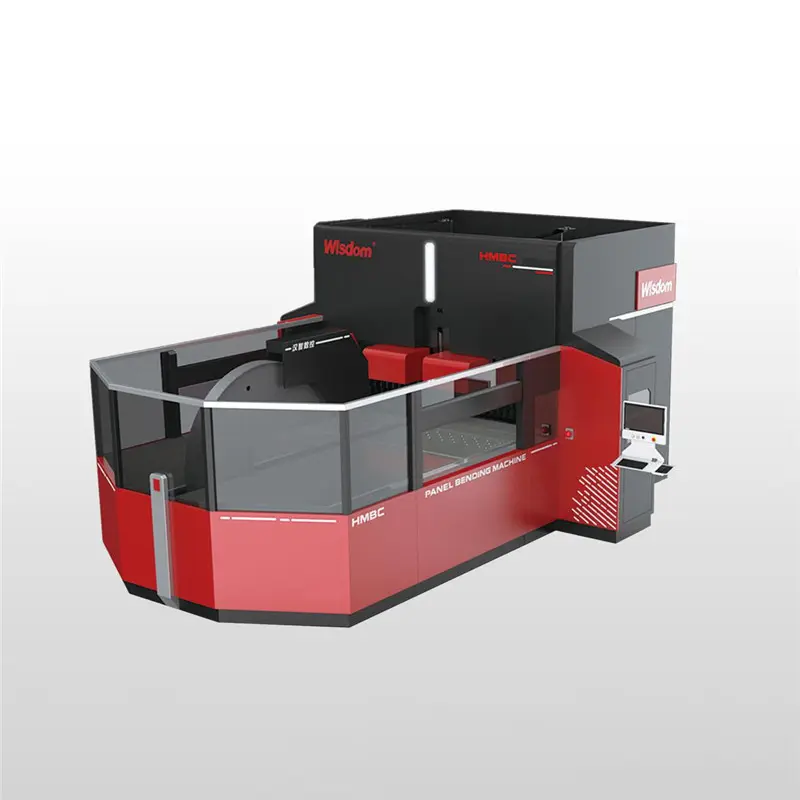

The modular design of the sheet metal panel benders can easily adapt to different production requirements. Interchangeable tool sets allow manufacturers to easily switch between different bend radii, angles and profiles. This flexibility opens up endless possibilities for customization and enhances the machine’s overall versatility.

Additionally, modern sheet metal panel benders are equipped with safety features to protect operators and minimize accidents. Sensors and safety guards are integrated into the machine to ensure operations are carried out in a safe environment. In addition, advanced control systems monitor the bending process in real time, providing critical data on machine performance and potential problems.

In short, the sheet metal bending machine has developed into an indispensable machine in the field of precision metal processing. These machines have revolutionized the manufacturing industry with unparalleled precision, automation and flexibility, allowing manufacturers to meet the growing demand for complex and customized products. As technology continues to advance, we can only imagine further advancements in the future, bringing more innovation to sheet metal bending machines and ultimately benefiting industries around the world.

Post time: Oct-25-2023