Introduce:

In the world of modern architecture and construction, there is a growing demand for unique, innovative and sustainable design solutions. One technology that is receiving a lot of attention is panel bending. Among the various methods available, Hand panel benders are considered the epitome of precision and craftsmanship. This blog post aims to delve into the world of manual panel bending machines, with a specific focus on their importance in forming aluminum composite panels.

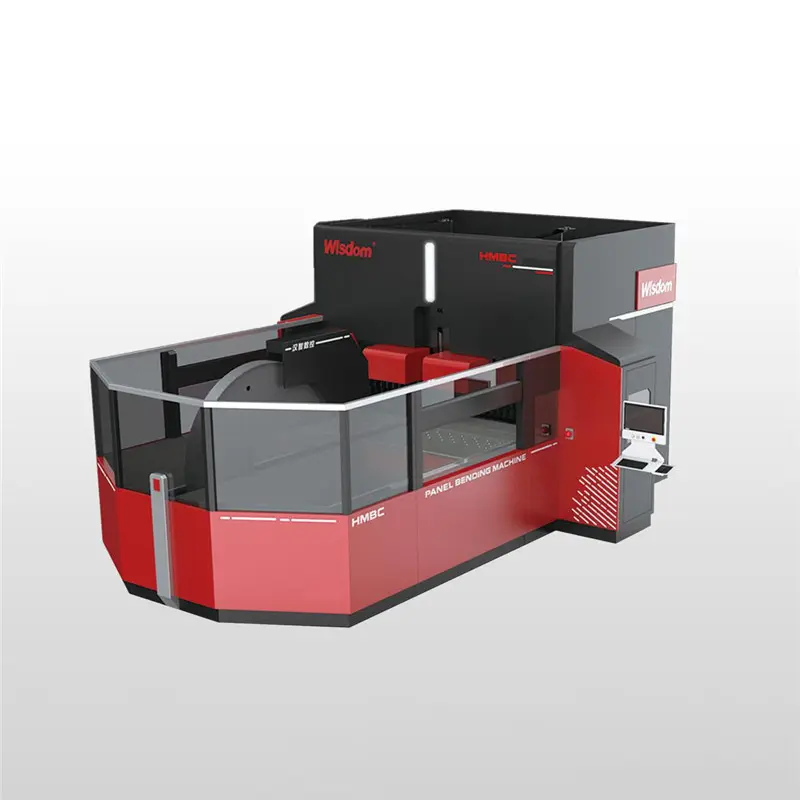

Understand the prototype bending machine:

Hand panel benders, also known as manual panel benders, are specialized tools used to bend and shape panels with the highest precision. Compared to automatic or hydraulic panel bending machines, manual panel bending machines rely on the expertise of skilled craftsmen to achieve the desired results. Mastery of this art is in the hands of experienced professionals who have an in-depth understanding of the material’s behavior, structure and the vast potential of aluminum composite panels.

The art and science of aluminum composite panel bending:

Aluminum composite panels (ACP) are becoming increasingly popular due to their high strength, durability and versatility. Shaping ACP using a manual panel bender offers many advantages, such as seamless transitions, custom designs and intricate details. Whether creating custom shapes or precise curves, manual panel bending machines offer flexibility that is difficult to replicate with automated machines. This allows architects, designers and builders to transcend the limitations of traditional building materials and turn their visions into reality.

Advantages of manual bending machine:

1. Accuracy: Manual panel bending machines offer precise and intricate forming capabilities to create complex and artistically appealing structures not possible through automated methods.

2. Versatility: Manual press brakes are capable of handling panels of various thicknesses and lengths, providing architects and designers with unparalleled versatility in creating unique and beautiful structures.

3. Cost-effective: Unlike automated machines that require heavy investment, manual bending machines are relatively more affordable and can be used for both large-scale projects and smaller customization needs.

4. Environmental Sustainability: By using manual sheet bending machines, the construction industry can contribute to sustainable practices. Automated machines reduce energy consumption and waste production, making hand bending an environmentally friendly option.

The essence of craftsmanship:

Manual press brakes not only offer precision advantages, but also provide skilled craftsmen with a platform to showcase their expertise. These craftsmen blended technical knowledge and artistic talent to breathe life into stunning architectural marvels. The meticulous process of hand panel bending creates a symbiotic relationship between craftsmen and materials, resulting in bespoke designs that truly stand out.

In conclusion:

Manual press brakes provide architects, designers and builders with a special tool to turn their artistic visions into reality. As an irreplaceable method of forming aluminum composite panels, they offer the advantages of precision, versatility and sustainability. The synergy between craftsmen and their tools opens up endless possibilities in architectural design, creating stunning structures. In the ever-evolving world of construction, manual plate bending machines are a testament to the artistry and dedication required to shape the future of construction.

Post time: Sep-25-2023