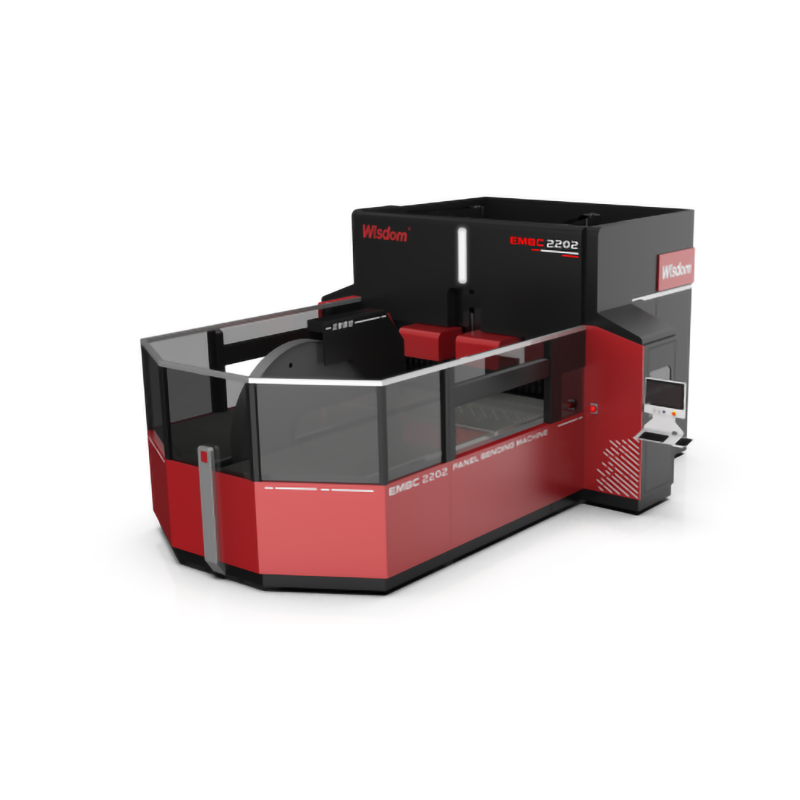

Introduce

In industrial manufacturing, precision and efficiency are critical. The constant demand for perfect results, especially when working with materials such as aluminum panels, has led to the development of advanced machinery. Today, we delve into the transformative power of CNC panel bending machines, which have revolutionized the way plate is bent. Through this article, we aim to explore the features, benefits and applications of these cutting-edge machines.

Highest accuracy

Sheet metal bending machines have long been an essential tool in the manufacturing industry. However, the introduction of CNC (computer numerical control) technology has taken precision bending to a whole new level. CNC panel bending machines offer incredible automation, allowing precise control of every step of the bending process. The machine is able to read and execute complex bending procedures with high precision, eliminating once inevitable human error. As a result, manufacturers can achieve consistent, high-quality aluminum sheet bends that exceed the capabilities of traditional press brakes.

Simplify the process

One of the most significant advantages of CNC panel bending machines is their ability to simplify the sheet bending process. These machines integrate the entire bending process, including loading, bending and unloading, into one automated system. This eliminates the need for multiple machines or manual labor, increasing productivity and reducing production time. By minimizing human intervention, manufacturers can maximize output while maintaining excellent quality standards.

Unlocking the potential of aluminum

Aluminum is a widely used material across industries due to its lightweight, durability and versatility. Due to its unique characteristics, traditional sheet metal bending machines often face challenges when processing aluminum. However, CNC panel bending machines have paved the way to achieve complex bends without compromising the integrity of aluminum panels. The precise control of CNC technology ensures high-quality bends, bringing versatility and efficiency to the aluminum industry.

Versatility and adaptability

CNC sheet bending machines offer exceptional versatility and adaptability, making them ideal for a variety of applications. These machines can handle a wide range of bends from simple to complex, adapting to different designs and projects. Whether manufacturing electrical enclosures, automotive parts or signage, CNC panel bending machines can adapt to a variety of bending angles and radii, ensuring production flexibility. With advanced control systems, operators can easily switch between jobs, maximizing efficiency and minimizing downtime.

Embrace the future

The emergence of CNC bending machines has redefined the process of industrial manufacturing. Their precision, automation and versatility make them an indispensable asset in industries such as aerospace, automotive and construction that demand flawless results. As technology continues to advance, these machines are expected to be further improved to meet the changing needs of the industry.

In conclusion

Precision, efficiency and versatility are the foundations on which CNC press brakes are reshaping manufacturing. By combining the power of automation and the accuracy of CNC technology, these machines unlock new possibilities in panel bending, particularly in aluminum machining. As we embrace the future, it is certain that CNC panel bending machines will continue to evolve, allowing manufacturers to achieve unprecedented levels of precision, productivity and innovation.

Post time: Nov-10-2023