Introduce:

In the field of metal manufacturing, high efficiency and high precision are always a priority. Manufacturers and manufacturers are always looking for innovative tools and machinery that can streamline processes and improve product quality. The manual press brake is one tool that revolutionized metal manufacturing. In this blog, we’ll dive into the importance of manual panel bending machines, their unique capabilities, and how they’ve become an integral part of the metal fabrication industry.

Efficiency and precision:

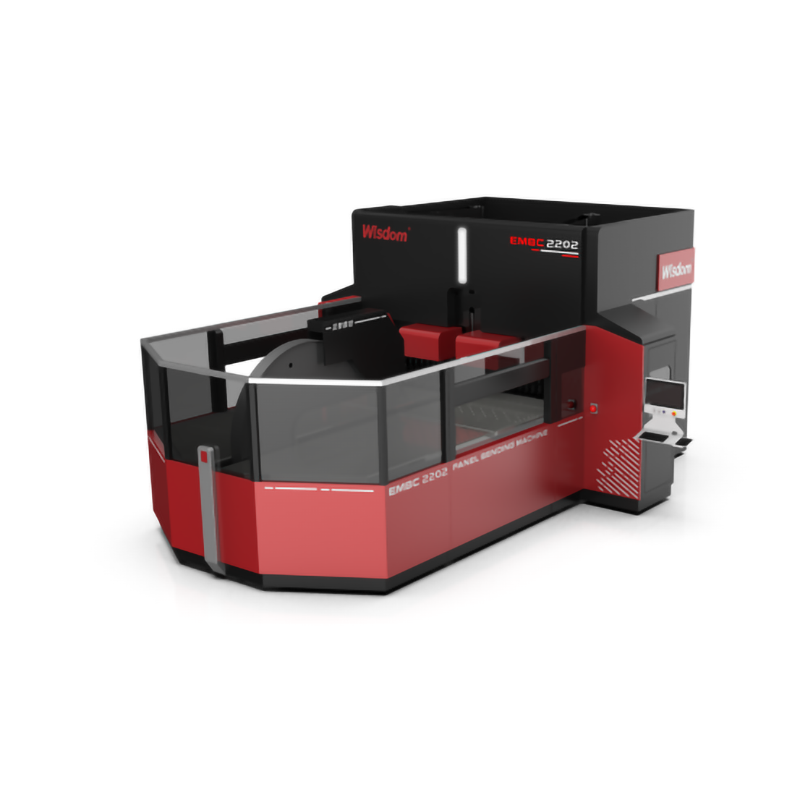

Hand panel benders herald a new era in metal fabrication by delivering efficiency and precision in one compact tool. Their design is simple and straightforward, consisting of two adjustable jaws that move relative to each other. By clamping a metal sheet between jaws and applying pressure, a press brake is able to bend the sheet at the desired angle with great precision. The introduction of manual press brakes has significantly reduced the time and effort required to form sheet metal, making the manufacturing process more efficient than ever.

Easy to use:

One of the undeniable advantages of a manual panel bender is its ease of use. Unlike traditional bending methods that require extensive training and specialized machinery, these bending machines are simple and user-friendly. Even a novice can easily create professional-looking bends in sheet metal by simply adjusting the jaws to the desired degree. The intuitive nature of these hand tools not only increases productivity but also lowers the barrier to entry for aspiring metal fabricators.

Versatility and portability:

Hand panel benders are versatile and can be used to bend various types of metals, including aluminum, steel, brass and copper. This versatility makes them ideal for a variety of applications, from fabricating complex metal parts to creating architectural elements with precise angles. Additionally, the compact size and portability of manual panel benders allow manufacturers to bring them to the job site, eliminating the need for bulky and expensive machinery. This flexibility results in significant cost savings and increased mobility for metal fabricators.

Cost-effectiveness:

In addition to the above advantages, manual press brakes offer a cost-effective solution for metal fabrication. Because they are manually operated, they require no electricity or other power source, reducing operating costs. Additionally, these tools last longer and require minimal maintenance compared to complex machines. Their durability ensures long-term cost savings for manufacturers, making them an attractive investment for businesses of all sizes.

In conclusion:

In summary, hand panel benders have dramatically changed the metal fabrication industry by delivering efficiency and precision in a user-friendly package. With their simple design, versatility and cost-effectiveness, these tools have become indispensable to manufacturers worldwide. As the demand for quality metal products continues to grow, manual sheet metal bending machines will undoubtedly play a vital role in meeting these requirements. By revolutionizing the way sheet metal is bent, these innovative tools are shaping the future of metal manufacturing.

Post time: Oct-21-2023